composite floor deck roll forming machine manufacturer

The Role of Composite Floor Deck Roll Forming Machines in Modern Construction

In the ever-evolving landscape of modern construction, the demand for efficient, durable, and cost-effective building materials has surged. One of the key innovations aiding this trend is the composite floor deck roll forming machine. These specialized machines play a vital role in producing composite floor decks, which serve as a crucial component in the structural integrity of buildings and civil engineering projects.

What Are Composite Floor Decks?

Composite floor decks are a type of structural flooring system that combines a metal deck with a layer of concrete. The metal deck, usually made from steel, provides tensile strength while the concrete layer contributes compressive strength, making it an efficient solution for minimizing material usage while maximizing load-bearing capabilities. This composite action allows for longer spans and reduced dead weight, leading to lower construction costs without compromising safety and performance.

The Function of Roll Forming Machines

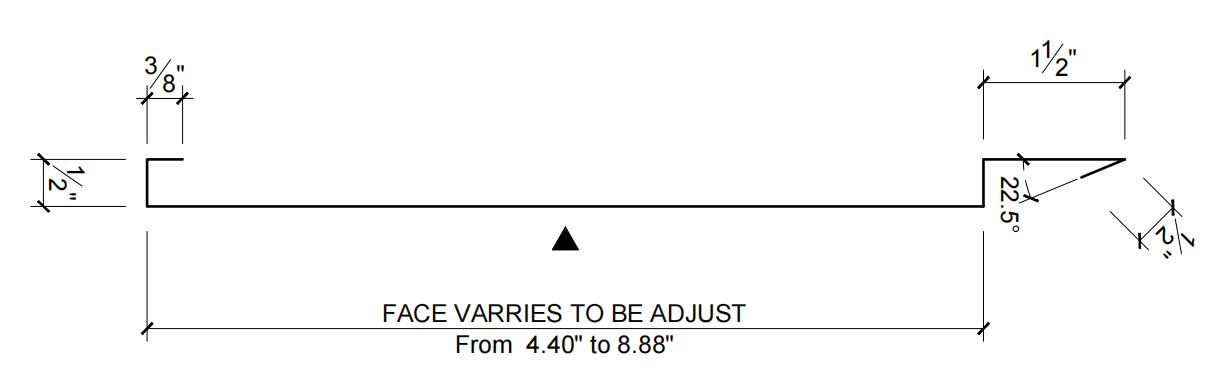

Roll forming machines are designed to transform flat metal sheets into desired shapes through a series of rollers. In the case of composite floor deck roll forming machines, they take metal sheets, often galvanized steel, and shape them into profiles that are specifically designed to support concrete slabs. This process is not only efficient but also highly automated, resulting in precise and uniform products.

Advantages of Using Roll Forming Machines

1. Efficiency and Speed One of the most significant advantages of using composite floor deck roll forming machines is the speed at which they can produce flooring components. The continuous nature of the roll forming process allows for high production rates, which can significantly reduce construction timelines.

composite floor deck roll forming machine manufacturer

2. Consistency and Precision These machines are engineered to deliver consistent results, ensuring that each piece of deck produced meets the specified dimensions and quality standards. This uniformity is critical in construction, where even slight variations can lead to structural issues.

3. Material Savings By using roll forming technology, manufacturers can minimize waste. The ability to produce components on-demand leads to better management of raw materials, contributing to overall cost savings and a reduction in environmental impact.

4. Versatility Composite floor deck roll forming machines can be customized to produce various profiles and thicknesses, allowing manufacturers to cater to specific project requirements. This adaptability makes them an invaluable asset to construction companies looking to meet diverse client needs.

Looking for a Manufacturer

When sourcing a composite floor deck roll forming machine, it is essential to consider the manufacturer’s reputation, experience, and technological capabilities. A reliable manufacturer should provide machines that not only offer high performance but also adhere to international quality standards. Additionally, the availability of after-sales services, technical support, and spare parts is crucial in ensuring the smooth operation of the machinery.

Conclusion

The use of composite floor deck roll forming machines represents a significant advancement in the construction industry. As buildings become taller and more complex, the need for efficient and reliable flooring solutions will only grow. These machines not only enhance productivity but also contribute to creating safer, more sustainable structures. As technology continues to improve, we can expect to see even more innovations in composite decking, further transforming the construction landscape for years to come.

In conclusion, investing in composite floor deck roll forming machines is not just a strategic decision for manufacturers but a leap toward enhancing construction efficiency and quality in an increasingly competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025