Composite Floor Deck Roll Forming Equipment Manufacturing Solutions for Efficient Construction Processes

The Role and Importance of Composite Floor Deck Roll Forming Machines in Construction

Composite floor decks have revolutionized the construction industry by offering lightweight solutions that maintain structural integrity and enhance the overall efficiency of building projects. At the heart of the production of these innovative decking solutions lies the composite floor deck roll forming machine, a critical piece of machinery in modern construction factories.

What is a Composite Floor Deck Roll Forming Machine?

A composite floor deck roll forming machine is specifically designed to produce floor deck panels from steel or other materials through a continuous rolling process. These machines take flat metal strips and progressively shape them into desired profiles. The result is a series of steel sheeting that can be used as structural flooring components in buildings and other structures.

Key Features of Composite Floor Deck Roll Forming Machines

1. Precision and Consistency One of the most significant advantages of using roll forming machines is their ability to create uniform products. The precision in manufacturing ensures that each panel meets the required specifications, thereby reducing waste and ensuring a consistent quality across all produced panels.

2. Efficiency Roll forming machines are known for their high production rates. They can produce a large number of panels in a short period, which is crucial for meeting tight project deadlines in the construction industry. This efficiency not only saves time but also contributes to cost-effectiveness.

3. Versatility These machines can be designed to create a variety of profiles, accommodating different architectural and engineering needs. This versatility enables builders to select designs that match specific project requirements, whether it be for residential buildings, commercial spaces, or industrial structures.

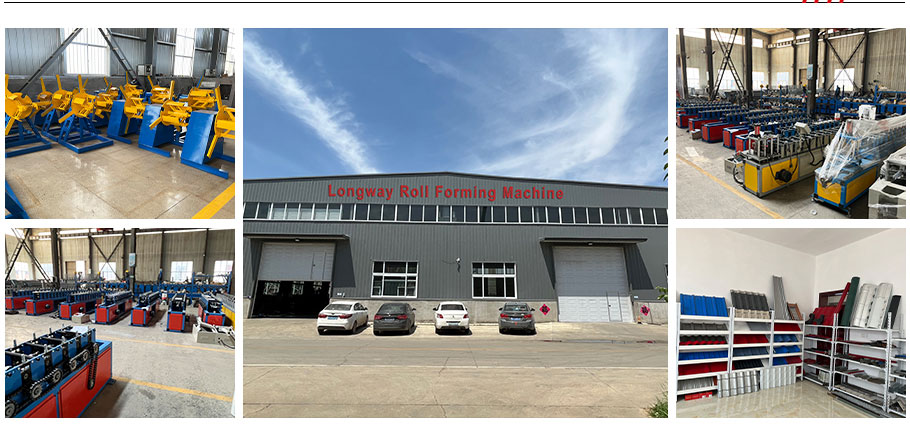

composite floor deck roll forming machine factory

4. Durability The materials used in the roll forming process are often selected for their strength and resistance to environmental factors. This durability ensures that the composite floor decks can withstand heavy loads and adverse conditions, making them suitable for a wide range of applications.

The Benefits of Using Composite Floor Decks

Composite floor decks offer several advantages over traditional flooring systems. They are typically lighter, which reduces the overall load on the building structure, allowing for more flexible design options. Additionally, the speed at which these decks can be installed translates into shorter construction times and reduced labor costs.

Furthermore, by providing a flat, continuous surface, composite floor decks facilitate easier installation of various finishes and contribute to the overall aesthetics of a space. This makes them a popular choice among architects and builders seeking both function and form.

The Future of Composite Floor Deck Roll Forming Machines

As the demand for innovative building solutions continues to grow, the technology behind composite floor deck roll forming machines is also advancing. Modern machines are increasingly automated, requiring less manual intervention and reducing the potential for human error. The integration of smart technology will likely play a significant role in future developments, enabling remote monitoring and data analysis to optimize production efficiency.

In conclusion, the composite floor deck roll forming machine is an indispensable asset in the construction industry, enabling the efficient and accurate production of essential building components. As construction techniques evolve and the need for sustainable and efficient materials increases, these machines will continue to play a pivotal role in shaping the future of building design and construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025