color steel profile roll forming machine

Color Steel Profile Roll Forming Machine Revolutionizing Construction

In the modern construction industry, the need for durable, efficient, and aesthetically pleasing materials has never been greater. Among the innovative solutions available, the Color Steel Profile Roll Forming Machine stands out as a transformative technology. This machine, designed to produce various profiles from color-coated steel sheets, has become essential for manufacturers and builders alike.

Understanding the Technology

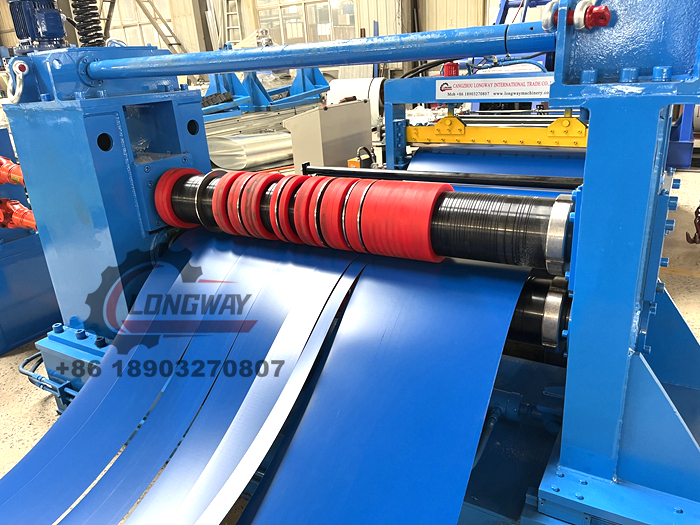

The Color Steel Profile Roll Forming Machine utilizes a continuous process in which steel sheets are fed into a series of rollers that gradually shape the sheet into the desired profile. The machine operates on the principle of cold forming, meaning that the metal is shaped without being heated. This method preserves the integrity of the steel, ensuring that its strength and flexibility are maintained.

Typically, the process begins with the uncoiling of a color-coated steel sheet. The sheets are usually pre-painted, which adds to their aesthetic appeal and protects against corrosion. The uncoiling process leads to the feeding of the steel into the machine, where it passes through a series of rollers. Each roller is meticulously designed to gradually bend and shape the steel into the final profile, such as roof panels, wall panels, or structural components.

Versatility and Customization

One of the most significant advantages of the Color Steel Profile Roll Forming Machine is its versatility. Manufacturers can produce a wide range of profiles suitable for various applications. From residential roofing to commercial construction, the profiles can be customized to meet specific project requirements. This adaptability is further enhanced by the machine's capability to handle different gauges and types of materials.

color steel profile roll forming machine

Moreover, as the construction landscape continues to evolve, the demand for energy-efficient and environmentally friendly materials has increased. Color-coated steel offers excellent insulation properties and is fully recyclable, making it a favorite choice for green building projects. The roll forming process itself generates minimal waste, further contributing to its sustainability.

Efficiency and Cost-Effectiveness

In today's competitive market, efficiency is key. The Color Steel Profile Roll Forming Machine is known for its high-speed production capabilities, allowing manufacturers to produce large quantities of profiles in a short amount of time. This rapid output not only meets market demand but also significantly reduces labor costs. The automated nature of the machine minimizes human intervention, resulting in lower chances of errors and rework.

Investing in a roll forming machine can lead to considerable cost savings in the long run. The initial investment may seem significant, but the durability of the profiles produced—combined with their low maintenance requirements—results in reduced costs associated with repairs or replacements over time.

The Future of Construction

As the construction industry continues to advance, the role of the Color Steel Profile Roll Forming Machine is likely to expand. With ongoing innovations, manufacturers are exploring new coating technologies and profile designs that cater to specific architectural trends. Additionally, the integration of smart technology and automation is expected to enhance the efficiency and capabilities of these machines further.

In summary, the Color Steel Profile Roll Forming Machine is an invaluable asset in modern construction. It combines efficiency, versatility, and sustainability to meet the evolving needs of the industry. As more builders and manufacturers recognize the benefits of using color-coated steel profiles, the demand for this technology will continue to grow, paving the way for a more innovative and eco-friendly construction landscape. The future is bright for roll forming, and those who embrace this technology will undoubtedly lead the way in creating the buildings of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025