Suppliers of Cold Roll Forming Machines for Efficient Metal Fabrication Solutions

Understanding Cold Roll Forming Machine Suppliers A Comprehensive Guide

Cold roll forming is a highly efficient manufacturing process that involves shaping and forming metal materials at room temperature. As industries require more complex shapes and profiles, cold roll forming machines have become essential tools in modern fabrication. This article explores the significance of cold roll forming machine suppliers and what to consider when selecting a reliable provider.

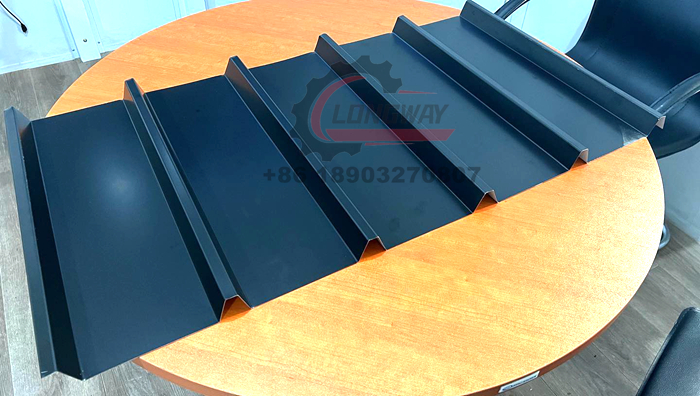

What is Cold Roll Forming?

Cold roll forming involves continuously feeding a flat metal strip through a series of rollers to create a desired cross-sectional shape. Unlike other metal forming processes, cold roll forming maintains the metal's integrity by working at lower temperatures, which reduces the likelihood of defects and enhances overall material properties. This method is ideal for producing various components used in sectors such as construction, automotive, and manufacturing.

The Role of Suppliers

Suppliers of cold roll forming machines play a crucial role in the supply chain

. They provide not only the machinery itself but also the technical expertise needed to optimize the forming process. A good supplier will offer a range of machines suitable for different applications, ensuring that businesses can scale their production based on demand.Key Considerations When Choosing a Supplier

1. Quality of Machinery The primary factor to consider is the quality of the cold roll forming machines. Look for suppliers who offer robust and durable equipment built from high-quality materials. Machines that are well-engineered can operate at high speeds while maintaining precision in each roll pass.

2. Customization Options Different projects may require different profiles. A reputable supplier will offer customization options, allowing clients to tailor the machinery to their specific needs. This feature can be crucial for businesses seeking to produce unique shapes or designs that set them apart from competitors.

cold roll forming machine suppliers

3. Technical Support and Service Beyond the sale, the supplier's customer support is vital. Seek suppliers who provide comprehensive technical support, including installation, maintenance, and troubleshooting. A strong after-sales service can minimize downtime, ensuring production processes run smoothly.

4. Industry Reputation Research the supplier's reputation in the industry. Look for reviews, testimonials, or case studies from previous clients. A supplier with a proven track record is often indicative of reliability and quality.

5. Innovation and Technology The world of manufacturing is constantly evolving, and suppliers who invest in the latest technology can provide their clients with competitive advantages. Look for suppliers that offer modern features such as automated control systems, energy-efficient designs, and user-friendly interfaces.

6. Cost-Effectiveness While quality should never be compromised, it is essential to find a supplier that offers competitive pricing. Evaluating the total cost of ownership, including initial investment, maintenance costs, and operational efficiency, can help in making the right choice.

7. Supply Chain Capabilities Choose suppliers who can ensure a steady supply of parts and machinery. Consistent availability is crucial for businesses that rely on just-in-time manufacturing practices.

Conclusion

The right cold roll forming machine supplier can significantly impact a business’s efficiency, production quality, and adaptability to market changes. By considering the above factors carefully, companies can establish partnerships that not only meet their immediate needs but also contribute to their long-term success. Investing in high-quality machinery from reputable suppliers is a strategic decision that will pay off in improved productivity and profitability. As industries continue to demand advanced solutions for complex shaping needs, the role of cold roll forming machine suppliers will only become more vital.

By selecting a dependable supplier, businesses can ensure they are well-equipped to meet the challenges of today’s competitive landscape, making them leaders in their respective fields.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025