cold roll forming machine exporter

The Rise of Cold Roll Forming Machine Exporters Innovations and Global Opportunities

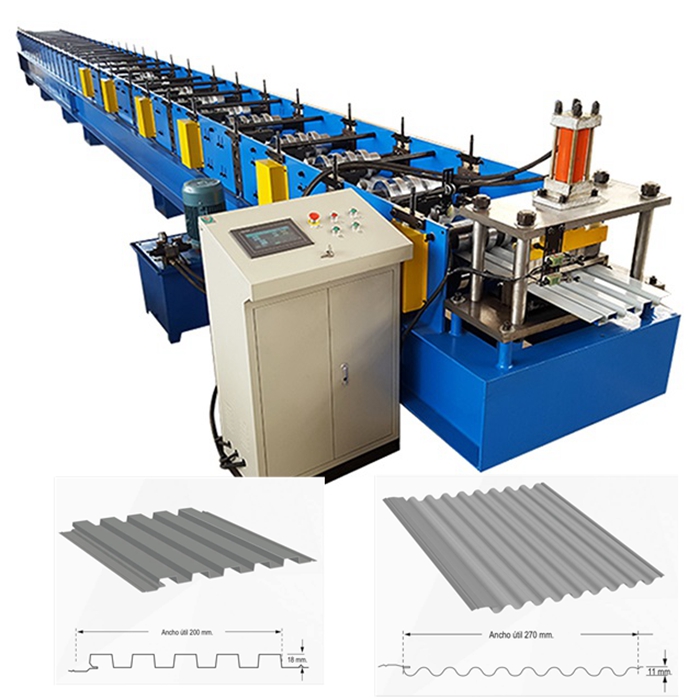

In recent years, the manufacturing sector has witnessed significant advancements, particularly in the area of metal processing. One of the standout technologies transforming the industry is the cold roll forming machine. These machines are crucial for producing high-precision metal components used in various applications, from construction to automotive parts. As a result, the demand for cold roll forming machine exporters has surged, presenting both challenges and opportunities in the global market.

Cold roll forming is a method where metal strips are gradually shaped into desired profiles through a series of rolling processes without the need for heating. This technique not only enhances the structural integrity of the materials but also allows for intricate designs and tighter tolerances compared to traditional forming methods. The applications of cold roll formed products are diverse; they are essential in building frames, roof trusses, and even specialized machinery components.

With the growing demand for energy-efficient and cost-effective manufacturing processes, industries are increasingly seeking reliable cold roll forming machine exporters. These exporters provide state-of-the-art machinery that addresses the specific needs of their clients. For instance, advanced cold roll forming machines offer automated features, reducing labor costs and increasing productivity. Furthermore, improvements in technology allow for better material yield and waste reduction, making the overall process more sustainable.

Exporters of cold roll forming machines face the challenge of adapting to different markets and regulatory environments. Countries like China, Germany, and the United States are leading manufacturers in this field, yet emerging markets are showing promising growth. These regions are investing in infrastructure and manufacturing capabilities, thereby increasing their demand for high-quality metal forming solutions. Therefore, exporters must navigate various international standards and customer preferences to succeed.

cold roll forming machine exporter

To capitalize on the growing market, cold roll forming machine exporters should focus on innovation and adaptability. This includes not only providing machines that meet the current technological standards but also offering flexibility to cater to custom requirements. Many successful exporters have started integrating Industry 4.0 principles into their machines, paving the way for smarter manufacturing solutions. Features such as IoT connectivity, real-time monitoring, and advanced data analytics can significantly boost the attractiveness of their products.

Moreover, establishing strong partnerships is vital for exporters aiming to penetrate new markets. Collaborating with local distributors or manufacturers can enhance market entry strategies, provide valuable insights into local customer behaviors, and streamline supply chains. Additionally, participating in trade shows and industry exhibitions can help exporters showcase their innovations, expand their network, and explore new business opportunities.

As global environmental concerns continue to rise, exporters of cold roll forming machines must also consider sustainability practices in their manufacturing processes. Developing energy-efficient machinery that minimizes emissions and waste will not only appeal to eco-conscious clients but also align with global efforts toward sustainable industrial practices.

In summary, the future of cold roll forming machine exporters looks promising, driven by technological advancements and a growing global demand for efficient manufacturing solutions. By embracing innovation, adapting to market needs, and fostering collaborations, these exporters can navigate the complexities of international markets while contributing to the evolution of the metal processing industry. The next few years will undoubtedly shape the landscape of cold roll forming, offering exciting prospects for those ready to embrace the change.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025