Cold Rolled Steel C Section Roll Forming Equipment for Efficient Production

Cold Rolled Steel C Section Roll Forming Machine A Comprehensive Overview

Cold rolled steel C sections are widely used in various construction and manufacturing applications due to their strength, lightweight properties, and cost-effectiveness. The process of producing these C sections involves advanced machinery known as cold rolled steel C section roll forming machines. These machines are pivotal in creating uniform and precise C-shaped steel profiles that meet the specific requirements of different industries.

A cold rolled steel C section roll forming machine operates by continuously bending and shaping a flat strip of steel into a C-profile through a series of rollers. The key advantage of cold rolling is that it enhances the mechanical properties of the steel, resulting in higher strength and improved finish compared to hot rolled steel. This makes cold rolled steel an ideal choice for structural components, frames, and supports in the construction sector.

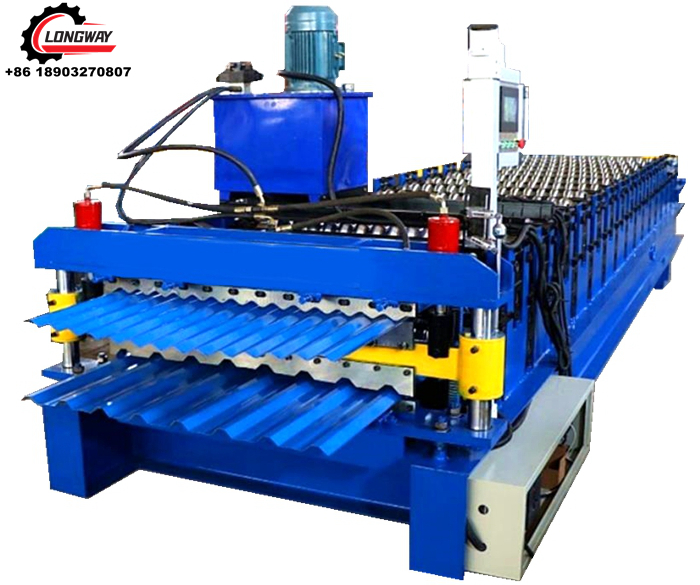

The design of these roll forming machines can vary depending on the production needs, but the fundamental components remain similar. Typically, a roll forming machine consists of a feed mechanism, a set of rollers, a cutting system, and a control panel. The feed mechanism pulls the steel strip through the rollers, which gradually shapes it into the desired C section. Each roller is specifically designed to perform a particular bending task, ensuring that the final product meets exact specifications.

One of the significant benefits of using a cold rolled steel C section roll forming machine is the efficiency it brings to production. These machines can operate at high speeds, significantly reducing manufacturing time while maintaining accuracy. Furthermore, the automation of the process minimizes the need for manual labor, which not only cuts costs but also increases safety in the production environment.

cold rolled steel c section roll forming machine

In addition to efficiency, roll forming machines are highly adaptable. They can be adjusted to produce different sizes and gauges of C sections without extensive downtime. This flexibility is crucial in today's fast-paced manufacturing landscape, where the demand for customized solutions is ever-growing. Manufacturers can easily switch between product lines, enabling them to respond quickly to market changes.

Moreover, the cold rolling process results in minimal material waste, making it an environmentally friendly option in the steel production industry. The precise cutting and shaping of steel strips not only conserve resources but also allow for recycling and repurposing of leftover materials.

As the construction and manufacturing industries continue to evolve, the demand for cold rolled steel C sections will likely increase. Investing in advanced cold rolled steel C section roll forming machines will allow manufacturers to remain competitive by producing high-quality products efficiently and sustainably.

In summary, cold rolled steel C section roll forming machines play a critical role in modern manufacturing. Their ability to produce strong, lightweight, and precise steel profiles quickly and with minimal waste makes them an invaluable asset in various industries. As technology advances, these machines will continue to adapt and improve, shaping the future of steel production.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025