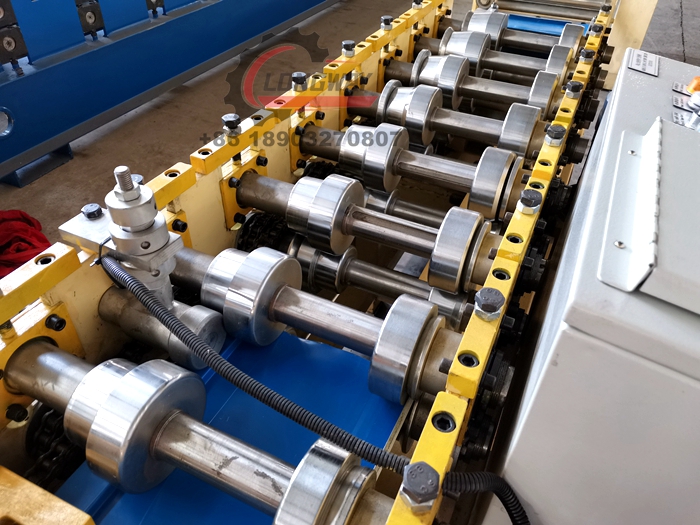

cold rolled steel channel framing roll forming machine

The Evolution of Cold Rolled Steel Channel Framing Roll Forming Machines

In the realm of modern construction and manufacturing, efficiency and innovation play pivotal roles in shaping the industry. Among the cutting-edge technologies making substantial waves is the cold rolled steel channel framing roll forming machine. This machine embodies a blend of precision engineering and versatile usage, showcasing its importance in various applications, from commercial buildings to residential projects.

The Basics of Roll Forming

Roll forming is a continuous bending process in which a long strip of metal, typically coiled steel, passes through a series of rollers. These rollers gradually shape the strip into a desired cross-sectional profile. Cold rolled steel, specifically, refers to steel that has been processed at room temperature, resulting in enhanced dimensional precision and improved surface finish. This method is particularly beneficial for channel framing, which requires high strength and precision in structural applications.

Advantages of Cold Rolled Steel Channel Framing

The choice of cold rolled steel channels in construction offers numerous advantages. First and foremost is their strength-to-weight ratio, which makes them ideal for various structural applications. Cold rolled channel sections exhibit excellent mechanical properties, allowing for the construction of lighter yet robust frameworks. This quality is especially vital in large projects where weight reduction can lead to lower foundation costs and improved energy efficiency.

Another significant advantage of cold rolled steel channels is their resistance to warping and deforming. Unlike hot rolled steel, which may experience dimensional changes as it cools, cold rolled steel maintains its shape throughout the manufacturing process. This stability ensures that the final product is consistently uniform, which is crucial for projects that demand precise tolerances.

Applications in Construction

Cold rolled steel channel framing roll forming machines are primarily used to create various channel profiles, which find extensive application in building frameworks, window and door frames, and other structural support systems. These channels are often employed in both load-bearing and non-load-bearing walls, contributing to the overall stability and integrity of the structure.

cold rolled steel channel framing roll forming machine

In commercial construction, cold rolled steel channels are particularly valued for their fire resistance and lightweight characteristics. They are regularly used in retail spaces, warehouses, and office buildings, where large open spaces require reliable support systems without excessive weight. Moreover, the corrosion resistance of coated cold rolled steel channels means that they can be employed in various environments, including those with high humidity or exposure to chemicals.

Automation and Precision Engineering

The evolution of technology in roll forming machinery has brought about significant advancements in automation and precision. Modern cold rolled steel channel framing roll forming machines are equipped with computer numerical control (CNC) systems, allowing for greater accuracy and customization. These machines can quickly switch between different profiles and dimensions, making them incredibly flexible and adaptable to varying project requirements.

Furthermore, the integration of automation streamlines production processes, reducing manual labor and increasing output efficiency. This technological shift not only enhances productivity but also mitigates human error, ensuring that every channel produced meets the high standards expected in today's construction industry.

Sustainability Considerations

As the construction industry faces increased scrutiny over its environmental impact, cold rolled steel framing solutions are gaining recognition for their sustainability. Steel is 100% recyclable, with recycled content contributing to a significantly lower carbon footprint compared to other building materials. Additionally, the manufacturing process of cold rolled steel channels generates less waste and energy consumption than traditional methods, making it an eco-friendly choice for builders and developers.

Conclusion

In summary, cold rolled steel channel framing roll forming machines represent a significant advancement in modern manufacturing and construction. Their superior strength, precision, and versatility make them indispensable in various applications, while their efficiency and sustainability align with the industry's future direction. As technology continues to evolve, these machines will undoubtedly play a crucial role in meeting the demands of an ever-changing construction landscape, ensuring that cold rolled steel channels remain at the forefront of structural innovation.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025