cladding roll forming machine manufacturer

The Importance of Cladding Roll Forming Machines in Modern Construction

In the ever-evolving landscape of construction and manufacturing, efficiency, precision, and durability are paramount. One of the pivotal technologies that meet these demands is the cladding roll forming machine. These machines have revolutionized how building materials are produced, particularly in the context of metal cladding, which is widely used for commercial and industrial buildings, as well as residential applications.

What is a Cladding Roll Forming Machine?

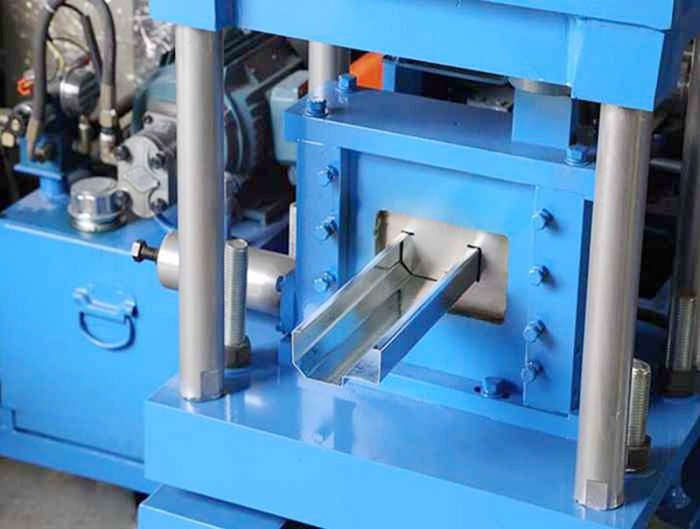

A cladding roll forming machine is a piece of equipment specifically designed to create metal sheets that are used as cladding for buildings. The process involves shaping metal strips into various profiles and structures by passing them through a series of rollers. The versatility of these machines allows manufacturers to produce an array of designs and dimensions tailored to specific architectural needs.

Advantages of Using Cladding Roll Forming Machines

1. High Efficiency One of the standout features of cladding roll forming machines is their ability to produce large quantities of material quickly. The automated nature of these machines significantly reduces labor costs and time frames, making them ideal for large-scale construction projects.

2. Precision and Consistency The advanced technology utilized in cladding roll forming machines ensures that every sheet produced meets strict specifications. This precision eliminates discrepancies that can arise in manual processes, leading to a uniform final product.

3. Material Versatility Cladding roll forming machines can work with a variety of metals, including steel, aluminum, and copper. This versatility allows architects and builders to choose materials that best fit the aesthetic and functional requirements of their projects.

4. Customization One of the key advantages of roll forming technology is the ease of customization. Manufacturers can create unique, bespoke profiles that cater to specific architectural designs, enabling them to stand out while also meeting performance needs such as weather resistance and insulation.

cladding roll forming machine manufacturer

5. Durability and Sustainability Metal cladding is known for its durability and low maintenance. The production process of cladding roll forming machines ensures that the resulting products can withstand the test of time, withstanding extreme weather conditions. Furthermore, metal is a recyclable material, contributing to more sustainable building practices.

Applications in Construction

Cladding produced from roll forming machines is used in a multitude of applications. It is commonly found in commercial buildings, where it serves as an exterior layer that provides thermal insulation and weather resistance. In residential projects, metal cladding adds a modern aesthetic while enhancing the home's energy efficiency.

Additionally, the industrial sector relies heavily on cladding systems for warehouses, factories, and storage facilities. The lightweight nature of the products allows for easy installation, further improving construction timelines.

Choosing a Cladding Roll Forming Machine Manufacturer

When selecting a cladding roll forming machine manufacturer, several factors should be considered. Quality should be at the forefront; a reputable manufacturer will use high-grade materials and components to ensure the longevity and reliability of their machines. Customer support is also vital; a manufacturer that offers prompt and efficient service can be invaluable, especially when issues arise during production.

Innovation and technology are equally important. The best manufacturers stay at the forefront of industry advancements, ensuring their machines incorporate the latest features and efficiency-enhancing technologies.

Conclusion

Cladding roll forming machines are integral to modern construction, providing a blend of efficiency, precision, and durability. As the demand for high-quality building materials continues to grow, the role of these machines becomes even more significant. By choosing a reliable manufacturer and leveraging the capabilities of roll forming technology, builders and architects can create structures that are not only aesthetically pleasing but also sustainable and long-lasting. In an industry where every detail matters, the importance of investing in quality cladding roll forming machines cannot be overstated.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025