cladding roll forming machine for sale factories

The Advancements and Opportunities in the Cladding Roll Forming Machine Industry

In the realm of modern construction and architectural design, cladding plays a pivotal role in enhancing aesthetics, insulation, and protection against the elements. As the demand for efficiently manufactured building materials continues to rise, the cladding roll forming machine has emerged as a critical component in the supply chain. This article explores the significance of cladding roll forming machines, their operational efficiency, technological advancements, and the thriving market for these machines.

Understanding Cladding Roll Forming Machines

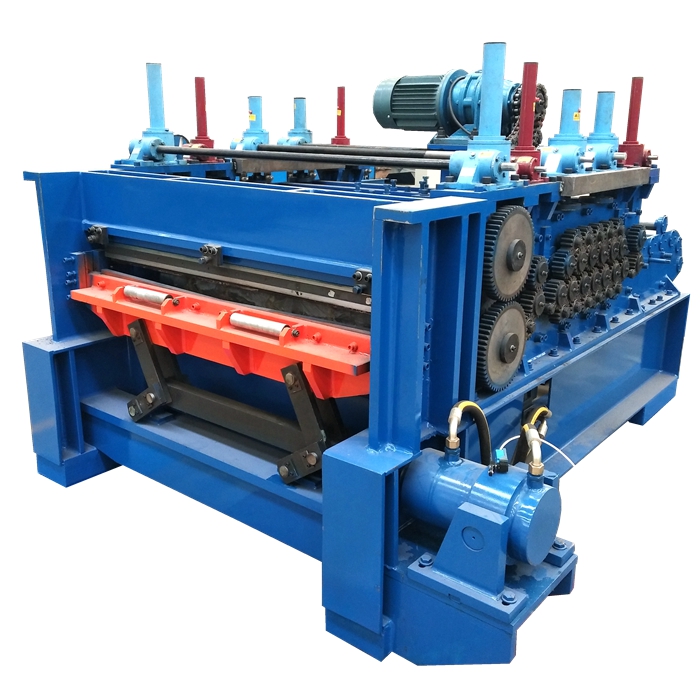

Cladding roll forming machines are specialized equipment used to produce metal cladding materials. These machines operate by feeding metal coils through a series of rollers, which shape and cut them into the desired profile. The resulting cladding panels can be utilized for a variety of applications, including facades, roofing, and wall systems. Their durability, resistance to corrosion, and low maintenance make them an attractive choice for contractors and builders.

The Importance of Efficient Manufacturing

As urbanization accelerates and construction projects become more complex, the need for efficient manufacturing solutions becomes paramount. Cladding roll forming machines significantly reduce production time and labor costs. By automating the roll forming process, these machines ensure consistent quality and precision, cutting down on waste and enhancing overall productivity. This efficiency allows manufacturers to meet the increasing demand for cladding materials without compromising on quality.

Technological Innovations

The market for cladding roll forming machines has witnessed remarkable technological advancements in recent years. Manufacturers have embraced automation, integrating features such as computer numerical control (CNC) systems and digital monitoring systems. These innovations allow operators to easily adjust the machine settings, optimize production runs, and reduce the risk of human error. Some machines are even equipped with advanced sensor technology, enabling real-time analytics and predictive maintenance, thus ensuring uninterrupted production.

Moreover, advances in material science have expanded the capabilities of cladding roll forming machines. New coatings and alloys have been developed to enhance the durability and aesthetic appeal of cladding materials. This flexibility allows manufacturers to cater to diverse architectural styles and clients' preferences. As sustainability becomes a critical consideration in construction, many manufacturers are also focusing on eco-friendly materials, further driving innovations in the cladding roll forming sector.

cladding roll forming machine for sale factories

The Market Landscape

The global market for cladding roll forming machines is on a growth trajectory, thanks in part to the booming construction industry and increased investment in renovation projects. Countries experiencing rapid urban development, such as China and India, are particularly significant consumers of these machines. Additionally, the rising trend of green building initiatives has spurred demand for sustainable cladding solutions that are feasible through advanced manufacturing technologies.

Furthermore, the prevalence of online platforms has made it easier for manufacturers and buyers to connect. Industrial suppliers can showcase their cladding roll forming machines through dedicated websites, reaching a broader audience while providing detailed specifications and pricing information. This accessibility aids in fostering competition, ensuring that buyers can find machines that best suit their production needs.

Opportunities for Growth

For manufacturers considering entry into the cladding roll forming machine market, the opportunities for growth are plentiful. Innovations in machine design, particularly regarding energy efficiency and smart technology, can greatly appeal to environmentally-conscious customers. Additionally, there is a growing demand for customization and versatility in machine offerings, prompting manufacturers to develop tailored solutions for specific applications.

The potential for automation and integration with other production processes presents another avenue for growth. By investing in research and development, companies can stay ahead of market trends and fulfill the evolving needs of clients.

Conclusion

Cladding roll forming machines represent a fundamental advancement in the construction materials industry. Their efficiency, adaptability, and increasingly sophisticated technological features make them indispensable in modern manufacturing. As the market for these machines continues to expand, stakeholders must remain attuned to innovations and changing consumer demands. Ultimately, those who embrace this momentum and commit to quality and efficiency will find themselves at the forefront of an exciting and dynamic industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025