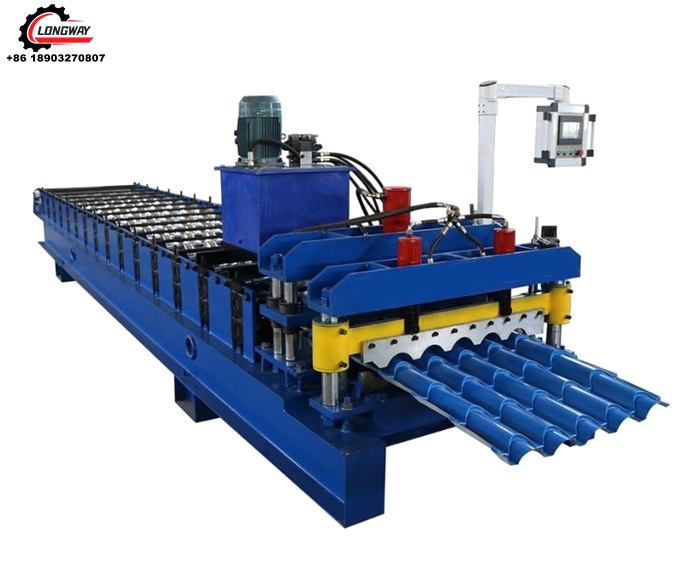

cladding roll forming machine

The Role of Cladding Roll Forming Machines in Modern Construction

Cladding roll forming machines are essential tools in the construction and manufacturing industries, providing efficient and precise solutions for fabricating metal cladding panels. These machines transform raw metal coils into finished cladding products, contributing significantly to the aesthetic and functional aspects of modern buildings. This article will explore the workings, advantages, and applications of cladding roll forming machines, highlighting their importance in today’s construction landscape.

What is a Cladding Roll Forming Machine?

A cladding roll forming machine is a type of industrial equipment designed to convert flat metal sheets or coils into shaped profiles that can be used for outer building surfaces. The process involves feeding a metal coil into the machine, which progressively shapes the material through a series of rollers. As the coil moves through the machine, it is gradually molded into a desired profile – typically used for wall panels, roofing systems, and insulation benefits.

These machines can produce various types of cladding, including standing seam panels, corrugated sheets, and decorative profiles, making them highly versatile for numerous applications.

How Does It Work?

The operation of a cladding roll forming machine is both straightforward and complex, emphasizing the precision of engineering involved. The process begins with the loading of metal coils into the uncoiler, which feeds the coil into the roll forming section. As the material traverses through the rollers, it undergoes bending and forming operations that shape it into the desired profile.

The machine may also include various auxiliary equipment, such as cutting tools that can shear the profiles to specific lengths, forming stations that add features like grooves or ribs, and conveyors that help manage the finished products. This seamless integration of various components allows for a continuous production process, enhancing efficiency and reducing waste.

Advantages of Cladding Roll Forming Machines

cladding roll forming machine

1. Efficiency Cladding roll forming machines operate at high speeds, allowing for rapid production of cladding materials. This efficiency is particularly beneficial in meeting tight deadlines in construction projects.

2. Precision These machines are engineered to deliver precise tolerances, ensuring that every panel is uniform in size and shape. This level of accuracy is crucial for proper installation and aesthetics.

3. Versatility With the ability to produce a wide range of profiles, cladding roll forming machines can cater to different architectural styles and construction requirements, making them valuable assets for manufacturers.

4. Material conservation The roll forming process minimizes material waste, as metal coils can be utilized efficiently to produce various profiles with minimal scrap.

Applications in Construction

Cladding roll forming machines find a multitude of applications in the construction industry. They are prominently used in creating facades, roofing systems, and wall panels for residential, commercial, and industrial buildings. The use of metal cladding enhances not only the structural integrity of buildings but also their energy efficiency, helping to reduce heating and cooling costs.

Additionally, these machines contribute to the aesthetic appeal of buildings, offering different finishes and colors that can complement any architectural style. As sustainability becomes more critical in construction, the durability and recyclability of metal cladding further position roll forming machines as essential technologies in creating eco-friendly building solutions.

Conclusion

In summary, cladding roll forming machines play a crucial role in modern construction, streamlining the production process of metal cladding while ensuring efficiency, precision, and versatility. As the construction industry continues to evolve, these machines will undoubtedly remain integral to meeting the demands of contemporary architecture and sustainable building practices. Investing in high-quality cladding roll forming technology is an investment in the future of construction, paving the way for innovative and resource-efficient building solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025