Jan . 11, 2025 10:31

Back to list

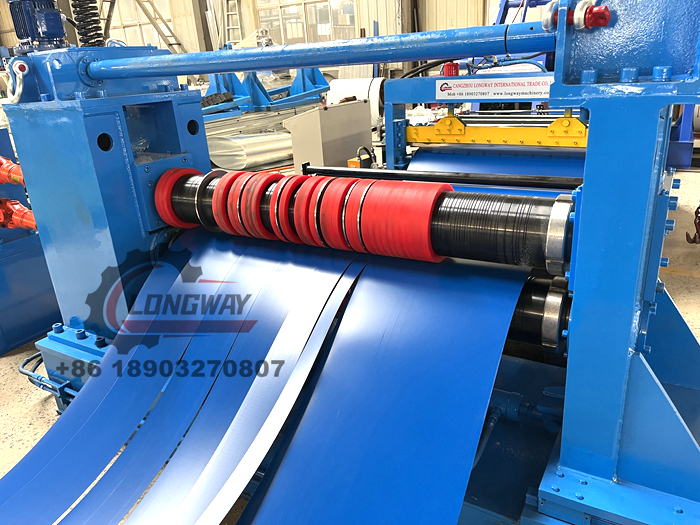

cladding roll forming machine

As industries continue to evolve at an unprecedented speed, the demand for quick, reliable, and precise manufacturing processes has never been higher. Among these advancements, the high-speed roll forming machine for CD UD profiles stands as a beacon of modern manufacturing efficiency. This piece of cutting-edge machinery is revolutionizing how construction and transportation industries operate by providing a streamlined method for producing light gauge metal profiles with unmatched speed and precision.

Furthermore, trustworthiness is a cornerstone attribute of these machines. Manufacturers who invest in high-speed roll forming technology are rewarded with dependable performance, minimal downtime due to maintenance needs, and robust design that withstands intensive industrial demands. These benefits collectively contribute to enhanced operational reliability and efficiency. Additionally, the incorporation of intuitive user interfaces in these machines is worth noting. Operators can manage settings, conduct routine maintenance checks, and troubleshoot issues with ease, demonstrating the blend of expertise and user-friendly design. This feature minimizes the learning curve for operators, streamlines training processes, and maximizes productivity from the get-go. Investing in a high-speed roll forming machine is a strategic decision for businesses aiming to enhance their production capabilities. It symbolizes a commitment to quality, efficiency, and technological advancement. With these machines, manufacturers are not only able to meet current market demands but are also equipped to scale operations as required in the future. In conclusion, the high-speed roll forming machine for CD UD profiles embodies the ideals of modern manufacturing speed, precision, versatility, and sustainability. As industries continue advancing, those equipped with such machinery will undoubtedly lead the charge, setting new standards in production excellence and operational authority while maintaining trust with clients and partners in delivering high-quality products.

Furthermore, trustworthiness is a cornerstone attribute of these machines. Manufacturers who invest in high-speed roll forming technology are rewarded with dependable performance, minimal downtime due to maintenance needs, and robust design that withstands intensive industrial demands. These benefits collectively contribute to enhanced operational reliability and efficiency. Additionally, the incorporation of intuitive user interfaces in these machines is worth noting. Operators can manage settings, conduct routine maintenance checks, and troubleshoot issues with ease, demonstrating the blend of expertise and user-friendly design. This feature minimizes the learning curve for operators, streamlines training processes, and maximizes productivity from the get-go. Investing in a high-speed roll forming machine is a strategic decision for businesses aiming to enhance their production capabilities. It symbolizes a commitment to quality, efficiency, and technological advancement. With these machines, manufacturers are not only able to meet current market demands but are also equipped to scale operations as required in the future. In conclusion, the high-speed roll forming machine for CD UD profiles embodies the ideals of modern manufacturing speed, precision, versatility, and sustainability. As industries continue advancing, those equipped with such machinery will undoubtedly lead the charge, setting new standards in production excellence and operational authority while maintaining trust with clients and partners in delivering high-quality products.

Next:

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products