china steel angle roll forming machine

Understanding the China Steel Angle Roll Forming Machine

In recent years, the demand for customized metal products has surged, leading industries to seek efficient and effective manufacturing solutions. One remarkable innovation in this field is the steel angle roll forming machine. Particularly prominent in China, these machines are pivotal in the production of steel angle sections, which are essential to a diverse range of applications, from construction to automotive industries. This article delves into the features, operation, benefits, and market trends surrounding steel angle roll forming machines in China.

What is a Steel Angle Roll Forming Machine?

A steel angle roll forming machine is specialized equipment designed to shape flat steel strips into angular profiles through a series of rollers. The end products, commonly known as steel angles, typically come in various dimensions and thicknesses, tailored to meet specific industry standards. These machines operate through a sequence of rollers, which progressively bend the metal strip into the desired angle, ensuring high precision and uniformity.

Key Features of Steel Angle Roll Forming Machines

Modern steel angle roll forming machines boast several advanced features that enhance their functionality and productivity

1. High Precision Equipped with advanced CNC (Computer Numerical Control) technology, these machines deliver high accuracy in shaping steel angles, ensuring minimal waste and high-quality output.

2. Robust Construction Built from durable materials, these machines can handle heavy-duty production environments, making them ideal for factories and large-scale manufacturing facilities.

4. User-Friendly Interface Most machines come with an intuitive control panel, making it easy for operators to program and modify settings for various production runs.

5. Energy Efficiency With a focus on sustainability, many modern machines are designed to consume less energy while maintaining high output levels.

How Does it Work?

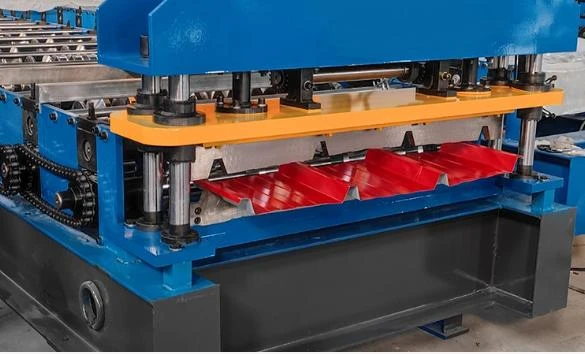

china steel angle roll forming machine

The operation of a steel angle roll forming machine is relatively straightforward. Initially, a flat steel strip is fed into the machine, where a series of rollers guide and bend the strip into the desired angle. This process typically consists of multiple passes through different sets of rollers, each designed to gradually increment the angle until the final shape is achieved.

The machine's controls allow for adjustments in speed, roller alignment, and pressure settings, which facilitate the production of steel angles in varying sizes and specifications. Additionally, some models may feature automated cutting systems that can shear the finished angles at preset lengths, streamlining the production process.

Benefits of Using Steel Angle Roll Forming Machines

1. Cost Efficiency By producing steel angles in-house, businesses can significantly reduce material costs and minimize waste.

2. Customization These machines enable manufacturers to create custom shapes and sizes, thereby addressing specific project requirements and increasing customer satisfaction.

3. Increased Production Speed The automated nature of roll forming machines allows for rapid production, meeting fluctuating market demands without sacrificing quality.

4. Improved Strength The roll forming process enhances the structural integrity of the steel angles, making them suitable for demanding applications.

Market Trends

The market for steel angle roll forming machines in China is on the rise, fueled by the rapid expansion of infrastructure projects and construction activities. Additionally, the push for eco-friendly manufacturing practices is driving innovations in machine design, promoting the development of more energy-efficient and sustainable options. As a result, manufacturers are increasingly investing in advanced technologies to enhance productivity and maintain a competitive edge in both domestic and international markets.

Conclusion

The steel angle roll forming machine is a vital asset in the modern manufacturing landscape, particularly in China. With its ability to produce high-quality steel angles efficiently and economically, it meets the growing demands of various industries. As technology continues to evolve, these machines will likely become even more versatile and efficient, further solidifying their place in manufacturing processes across the globe. Investing in a steel angle roll forming machine not only provides businesses with a competitive advantage but also contributes to the overall advancement of the metalworking industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025