Advanced Slitting Line Machines for Precision Metal Processing in China

The Evolution and Importance of China’s Slitting Line Machines in Modern Manufacturing

In recent years, the manufacturing industry has experienced significant transformations, particularly with the advent of advanced machinery that enhances efficiency and productivity. Among these innovations, slitting line machines have gained remarkable attention, especially in China. The slitting line machine is a vital piece of equipment used in the processing of metal coils, allowing manufacturers to cut coils into narrower and more manageable widths. This article delves into the evolution, benefits, and significance of these machines in China's burgeoning industrial landscape.

Historical Context

Historically, the need for efficient metal processing led to the development of slitting technology. In the past, manufacturers faced challenges related to the manual cutting of metal sheets, which was not only time-consuming but also prone to errors. As demand for precision and efficiency grew, the introduction of automated slitting line machines revolutionized the industry. China, being one of the largest producers of steel and metal products globally, quickly adapted this technology, leading to significant advancements in manufacturing capabilities.

Machine Components and Operation

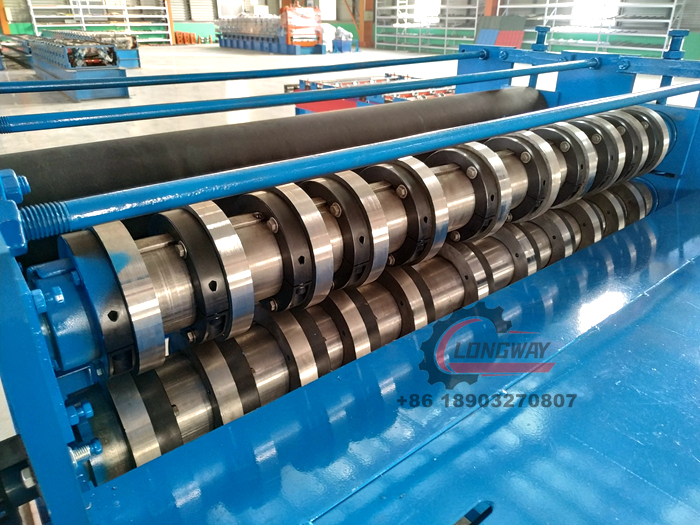

A typical slitting line machine consists of several critical components, including uncoilers, slitting heads, tension controls, and recoilers. The process begins with the uncoiling of a large metal coil, which is then fed into the slitting head where it is cut into smaller strips. The careful alignment and adjustment of blades ensure that the strips are cut to the desired width with remarkable precision.

The operation of slitting line machines is highly automated, reducing the need for manual intervention. This automation not only minimizes human error but also speeds up production times, allowing manufacturers to meet increasing market demands swiftly. Furthermore, modern slitting lines are equipped with advanced control systems that enhance operational efficiency and allow for quick adjustments during production.

Benefits of Slitting Line Machines

1. Increased Efficiency The automation and speed of slitting line machines significantly enhance operational efficiency. Tasks that once required many hours of manual labor can now be completed in a fraction of the time.

china slitting line machine

2. Precision Cutting Modern slitting line machines ensure high precision in cutting, thereby reducing material wastage. This precise cutting is crucial for industries that require specific dimensions for their components.

3. Versatility These machines can handle a variety of materials, including stainless steel, carbon steel, and aluminum, making them versatile tools in the manufacturing sector. This versatility allows companies to diversify their product offerings without needing to invest in additional machinery.

4. Cost-Effectiveness By reducing labor costs and increasing production rates, slitting line machines contribute to lower overall manufacturing costs. Additionally, the reduction in material waste leads to further savings.

Challenges and Future Directions

While the benefits of slitting line machines are evident, manufacturers in China face challenges such as rising energy costs and fluctuating raw material prices. To combat these issues, technology advancements focusing on energy efficiency and sustainable practices are being prioritized.

Furthermore, the future of slitting line machines will likely see the integration of artificial intelligence and machine learning. These technologies can provide data analytics for predictive maintenance, thus minimizing downtimes and optimizing performance.

Conclusion

As China continues to solidify its position as a manufacturing powerhouse, slitting line machines will play a critical role in shaping the industry’s future. With their ability to enhance efficiency, precision, and cost-effectiveness, these machines will not only meet the current demands of the market but will also pave the way for innovative manufacturing solutions. For businesses looking to thrive in an increasingly competitive environment, investing in advanced slitting line technology is not merely an option; it is a necessity. The evolution of these machines embodies the broader trends in the manufacturing landscape, showcasing the synergy between technology and industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025