china r panel roll forming machine

The Advancement of China’s R Panel Roll Forming Machines

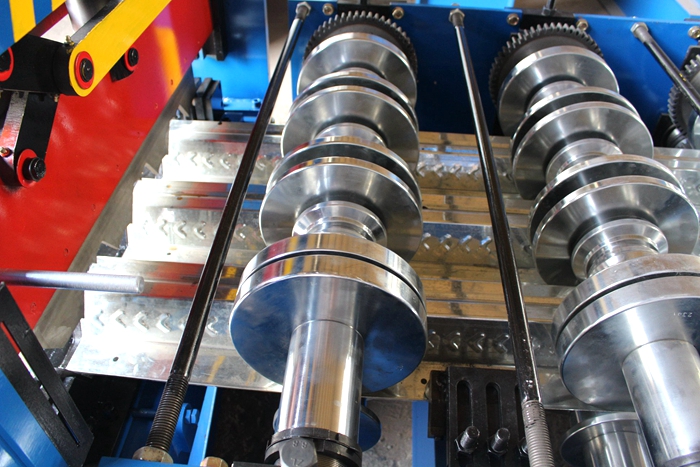

In recent years, the demand for high-quality building materials has surged, prompting manufacturers to innovate and streamline their production processes. Among the key advancements in the construction sector are China’s R panel roll forming machines, which have transformed the way panels are fabricated for various applications, including industrial buildings, warehouses, and even residential projects.

R panels, known for their ribbed design and exceptional durability, are a popular choice due to their structural integrity and aesthetic appeal. These panels, often made from steel, are lightweight yet strong, making them ideal for roofing and siding applications. The production of R panels requires precision engineering and efficient manufacturing processes, both of which are encapsulated in China’s advanced roll forming technology.

The Advancement of China’s R Panel Roll Forming Machines

One of the most notable features of China’s R panel roll forming machines is their versatility. These machines can accommodate various materials, including galvanized steel, aluminum, and even composite materials. This adaptability allows manufacturers to customize panels according to specific project requirements, catering to different aesthetic preferences and structural needs.

china r panel roll forming machine

Moreover, the efficiency of these machines plays a crucial role in reducing production costs. Automated systems integrated into the roll forming process minimize manual labor, speeding up the manufacturing time while maintaining high-quality standards. With the capability to produce long lengths of R panels in one continuous run, manufacturers can meet large-scale project demands without compromising quality or incurring excessive labor expenses.

The durability of R panels produced by these machines also contributes to their growing popularity. Coated with protective finishes, these panels resist corrosion, UV radiation, and other environmental factors, ensuring a long lifespan. This durability not only enhances the overall quality of construction projects but also reduces maintenance costs for property owners.

China’s roll forming machinery industry is not just focused on domestic sales; they are also expanding into international markets. The efficient and cost-effective machines are attracting attention from construction companies worldwide, seeking reliable solutions for their panel production needs. As globalization continues to shape the manufacturing landscape, the export potential of R panel roll forming machines promises to foster further advancements in technology and production techniques.

In conclusion, China’s R panel roll forming machines represent a significant leap forward in the construction materials industry. With their ability to produce high-quality, durable panels efficiently and cost-effectively, these machines are setting new standards in manufacturing. As the demand for sustainable and reliable building materials continues to grow, the roll forming machines will undoubtedly play a critical role in shaping the future of construction. As we move forward, it is imperative to keep an eye on these advancements, as they will likely influence construction practices around the globe.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025