China Light Keel Roll Forming Machine Manufacturers and Their Innovations

China Light Keel Roll Forming Machine Factories A Comprehensive Overview

The construction and manufacturing industries have experienced rapid growth in recent years, particularly in China. Among the various innovations that have emerged, the light keel roll forming machine has gained significant attention for its efficiency and effectiveness in producing metal framing systems. This article delves into the role of light keel roll forming machine factories in China, exploring their operations, technological advancements, and contributions to both domestic and international markets.

What are Light Keel Roll Forming Machines?

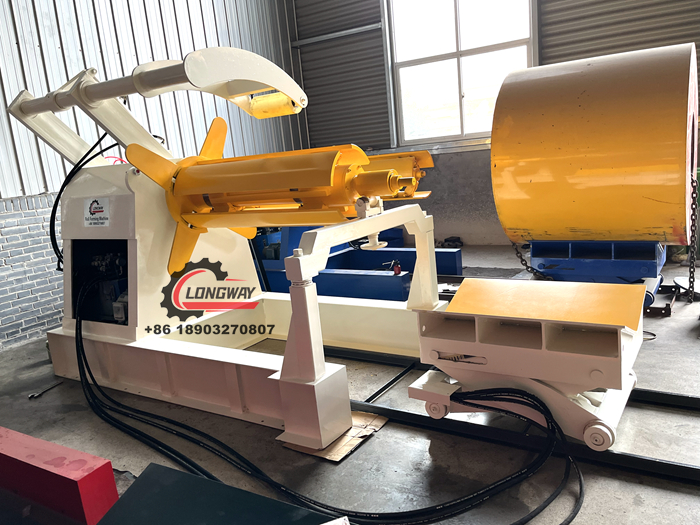

Light keel roll forming machines are specialized equipment used to produce light steel keels, which are essential components in drywall and false ceiling systems. These machines sequentially shape metal strips into various profiles, creating a robust and versatile framing solution for construction projects. The keels produced are lightweight yet strong, making them an ideal choice for non-load-bearing walls and ceiling structures.

The Rise of Roll Forming Technology in China

China's manufacturing capabilities have evolved substantially over the past few decades, with roll forming technology at the forefront of this transformation. The country's factories have invested heavily in advanced machinery and technology to meet the increasing demand for construction materials. This investment has enabled them to produce high-quality light keel framing systems that adhere to international standards.

Factory Operations and Technological Advancements

Chinese light keel roll forming machine factories utilize advanced production techniques to optimize efficiency and reduce waste. These factories are typically equipped with automated systems that streamline the manufacturing process. Computer Numerical Control (CNC) systems are widely used for precision cutting, bending, and shaping of metal strips, ensuring each product meets specific dimensional requirements.

Moreover, many factories have embraced innovations such as Industry 4.0 technologies. This integration of the Internet of Things (IoT), big data, and artificial intelligence into manufacturing processes has enhanced operational efficiency and product quality. Real-time monitoring of machines allows for predictive maintenance, minimizing downtime and improving productivity.

china light keel roll forming machine factories

Quality Control and Certifications

Quality control is a paramount concern for light keel roll forming machine manufacturers in China. To compete in the global market, factories implement stringent quality assurance processes throughout the manufacturing cycle. Many of these manufacturers have obtained certifications such as ISO 9001, which reflects their commitment to maintaining high quality and safety standards.

Additionally, factories often conduct rigorous testing on their machines before delivery. This includes checking for material durability, performance under stress, and compliance with international building codes. Such practices ensure that products are reliable and meet the expectations of customers both domestically and overseas.

Domestic and International Markets

The demand for light keel roll forming machines is not limited to China; these products are increasingly finding their way into international markets. Countries in Southeast Asia, the Middle East, and Africa are particularly interested in importing Chinese roll forming machines due to their cost-effectiveness and efficiency. Manufacturers in China are leveraging this demand by establishing partnerships and distribution networks across the globe.

In addition to exports, local construction businesses benefit greatly from the presence of these factories. The availability of locally manufactured light keel roll forming machines reduces lead times and costs for contractors and builders, facilitating faster project completion and greater flexibility in construction design.

Conclusion

China’s light keel roll forming machine factories play a crucial role in the modern construction landscape. With advanced technology, rigorous quality control measures, and a growing international presence, these factories are setting standards in metal framing system production. As the construction industry continues to evolve, the significance of these machines and the factories that produce them will remain paramount, driving innovation and efficiency in building practices worldwide.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025