China Light Weight Keel Roll Forming Equipment for Efficient Construction Solutions

The China Light Keel Roll Forming Machine An Overview

In the realm of modern construction and structural engineering, efficiency and precision play crucial roles. One of the machinery that encapsulates these qualities is the China light keel roll forming machine. This innovative tool has revolutionized the way light steel keels are produced, streamlining the manufacturing process while ensuring high quality in the final product.

What is a Light Keel?

Before delving into the machinery, it's important to understand what a light keel is. Light steel keels, often used in the construction of partition walls, ceilings, and other internal structures, are lightweight yet robust metal profiles. They are primarily made from galvanized steel or other corrosion-resistant materials, making them ideal for various applications in both commercial and residential buildings. Due to their lightweight nature, they offer structural efficiency and are conducive to quick and easy installation.

The Role of Roll Forming Machines

Roll forming is a continuous bending operation in which sheet or strip metal is gradually shaped into the desired cross-section. The process involves passing the metal sheet through a series of rollers that progressively form it into the desired profile. The China light keel roll forming machine exemplifies this technology by specifically targeting the production of light steel keels.

These machines are designed to maximize efficiency, producing high volumes of keels with precision and uniformity. The automation included in these machines reduces labor costs and minimizes the chances of human error, resulting in a more reliable manufacturing process.

Key Features of the China Light Keel Roll Forming Machine

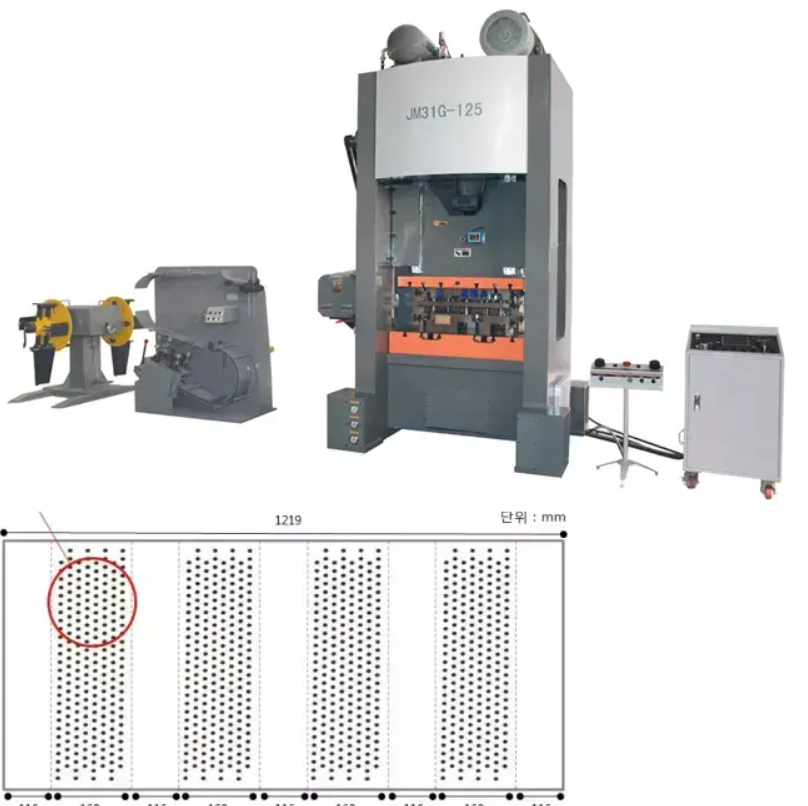

china light keel roll forming machine

1. High Precision Manufacturers have engineered China light keel roll forming machines with advanced technology that ensures the products meet strict tolerances. Key features such as automatic length measurement, advanced control systems, and synchronizing motors contribute to creating keels that fit perfectly during installation.

2. Versatility These machines can produce a variety of keel shapes and sizes, accommodating different construction needs. Whether it’s for a lightweight partition or a more robust structural application, manufacturers can adjust the machinery settings to meet custom requirements.

3. Durability and Quality Built with high-quality materials and components, these machines are designed for longevity. The use of durable rollers and high-strength steel ensures that the machinery can withstand the rigors of continuous operation.

4. Efficiency With the ability to operate at high speeds, these machines significantly cut down production time without compromising quality. Many models can produce hundreds of meters of keels per hour, making them ideal for mass production.

5. User-Friendly Control Systems Many newer models come equipped with touchscreen interfaces and programmable logic controllers (PLCs) that simplify the operation process. This user-friendly design allows workers with varying levels of expertise to operate the machine efficiently.

Conclusion

The China light keel roll forming machine is a testament to the technological advancements in the construction industry. By providing an efficient, precise, and cost-effective solution for producing light steel keels, these machines enhance productivity and contribute to the overall quality of construction projects. As the demand for light steel structures continues to grow, so too will the reliance on advanced manufacturing machinery like the light keel roll forming machine.

As construction methods evolve and the need for more sustainable, efficient solutions becomes more pronounced, it is clear that such technology will play a pivotal role in shaping the future of building practices. Whether for residential, commercial, or industrial applications, investing in a China light keel roll forming machine exemplifies a commitment to quality, innovation, and progress in the field of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025