china double layer roll forming machine

Understanding the China Double Layer Roll Forming Machine

In the realm of advanced manufacturing, roll forming has emerged as a highly efficient method for producing metal profiles, widely used in various industries, from construction to automotive. Among the myriad of machines developed for this purpose, the double layer roll forming machine stands out, particularly in China, due to its innovative design and versatility.

What is a Double Layer Roll Forming Machine?

A double layer roll forming machine is an advanced production line that allows manufacturers to create two different profiles simultaneously. This is achieved through a clever design that utilizes a single set of rollers to shape two layers of metal sheets, which flow through the machine at the same time. The result is a significant increase in production efficiency, enabling manufacturers to save on space, time, and costs.

Key Features and Advantages

1. Space Efficiency One of the most obvious benefits of a double layer roll forming machine is its compact design. By producing two profiles within the same machine setup, manufacturers can reduce the footprint of their production lines, which is particularly advantageous in limited workspace scenarios.

2. Cost-Effectiveness Due to the dual-layer functioning, this machinery minimizes operational costs. Manufacturers can produce two products with less labor and fewer resources compared to running two separate machines. This translates into lower overhead and higher profit margins.

3. Versatility Chinese manufacturers have developed a variety of double layer machines capable of producing many different kinds of profiles. The profiles can range from traditional roofing sheets to more complex sections used in construction, thus catering to diverse market needs.

4. High Production Speeds The technology behind double layer roll forming machines allows for rapid production speeds without compromising on the quality of the finished products. This is crucial in industries like construction, where time is often of the essence.

china double layer roll forming machine

5. Automated Control Many modern double layer roll forming machines feature advanced computerized systems for better control over production processes. This automation minimizes human error and enhances precision, ensuring that the final products meet strict quality standards.

Applications Across Industries

The flexibility offered by double layer roll forming machines makes them suitable for various applications. In the construction industry, they are often used to produce roofing systems, wall panels, and partition sections. Their ability to fabricate lightweight yet durable materials makes them particularly valuable in modern building practices.

In addition, the automotive industry utilizes these machines to create components that require both strength and lightweight characteristics. Other industries such as furniture manufacturing, HVAC systems, and agricultural equipment also benefit from the efficient and versatile nature of double layer roll forming technology.

The Chinese Manufacturing Landscape

China has cemented its status as a global leader in roll forming technology, largely due to its significant investment in manufacturing infrastructure and research and development. Chinese manufacturers are known for their ability to produce technologically advanced machinery at competitive prices. They have continuously improved the design and functionality of double layer roll forming machines, ensuring that they meet international standards and customer requirements.

Conclusion

The China double layer roll forming machine epitomizes the advancements in automated manufacturing, offering efficiency, versatility, and cost savings to industries worldwide. As the demand for high-quality metal profiles continues to grow, these machines will play an increasingly pivotal role in meeting that demand while ensuring sustainable production practices. In a rapidly evolving manufacturing landscape, investing in double layer roll forming technology might just be the competitive edge businesses need to thrive.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

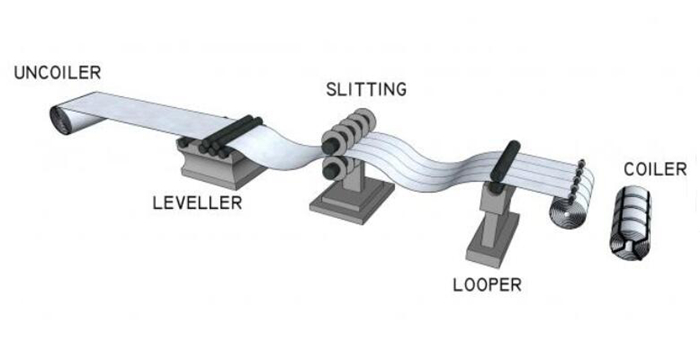

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025