china automatic roll forming machine

China's Automatic Roll Forming Machines Revolutionizing the Manufacturing Industry

In recent years, China's manufacturing sector has undergone a significant transformation, largely due to advancements in technology. One of the standout innovations contributing to this evolution is the automatic roll forming machine. These machines have not only streamlined production processes but have also set new standards for quality and efficiency in various industries.

What is an Automatic Roll Forming Machine?

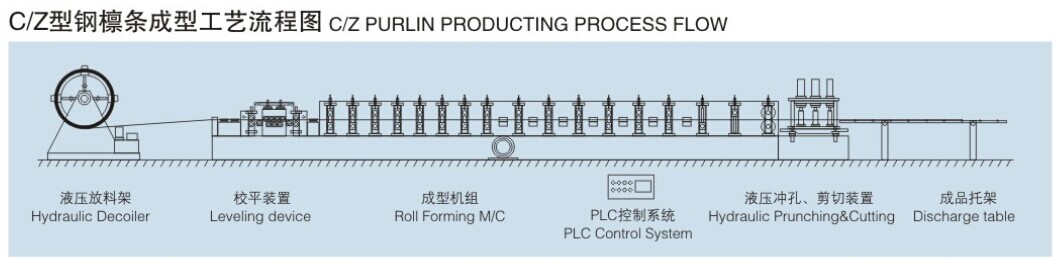

An automatic roll forming machine is a type of equipment that continuously forms sheets of metal into specific shapes through a series of rollers. Unlike traditional metalworking processes, which may involve cutting, welding, or machining, roll forming allows for a more efficient creation of complex shapes with minimal waste. This process is particularly beneficial for producing long, linear components such as roofing panels, wall studs, and floor decking, which are essential in construction and manufacturing.

Advantages of Automatic Roll Forming Machines

1. High Efficiency One of the most significant advantages of automatic roll forming machines is their high production efficiency. These machines can operate at a continuous rate, often producing meters of material in just a few minutes. With automated operations, manufacturers can achieve a higher output while reducing labor costs.

2. Precision Engineering Automatic roll forming machines are designed for precision. With the aid of computer numerical control (CNC) technology, these machines can produce components with exact dimensions and tolerances. This level of precision reduces the need for secondary operations, leading to overall cost savings and better product quality.

3. Versatility These machines can be adjusted to accommodate various materials, including steel, aluminum, and other metals. Additionally, manufacturers can easily change the tooling to produce different shapes, making the machines highly adaptable to different requirements in the market.

china automatic roll forming machine

4. Less Material Waste The continuous forming process is designed to minimize scrap. As the material is transformed into the desired shape without cutting it up, the overall material waste can be significantly reduced, contributing to both economic savings and environmental sustainability.

5. Integration with Modern Technology Many automatic roll forming machines are equipped with advanced technology, including IoT capabilities and data analytics. This integration allows manufacturers to monitor production in real-time, ensuring optimal performance and enabling predictive maintenance to reduce downtime.

Applications Across Industries

The applications of automatic roll forming machines are extensive and varied. In the construction industry, they are widely used to manufacture components like metal roofing systems, structural support elements, and wall panels. Automotive manufacturers use these machines to create parts that require high precision and durability, such as chassis components and frame rails. Additionally, the appliances and furniture industries benefit from roll forming technology to produce various metal parts that are both aesthetically pleasing and structurally sound.

Conclusion

In summary, China's automatic roll forming machines represent a significant leap in manufacturing technology, combining efficiency, precision, and versatility. As industries continue to evolve and seek ways to improve production processes, these machines are becoming increasingly essential. Whether for construction, automotive, or consumer goods, the innovative features and capabilities of roll forming machines are set to play a pivotal role in shaping the future of manufacturing in China and beyond.

As the global demand for high-quality, cost-effective products rises, China's investment in advanced manufacturing technologies like automatic roll forming machines will undoubtedly solidify its position as a leader in the international market. The future of manufacturing looks bright, thanks in part to these remarkable machines that continue to revolutionize how products are made.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025