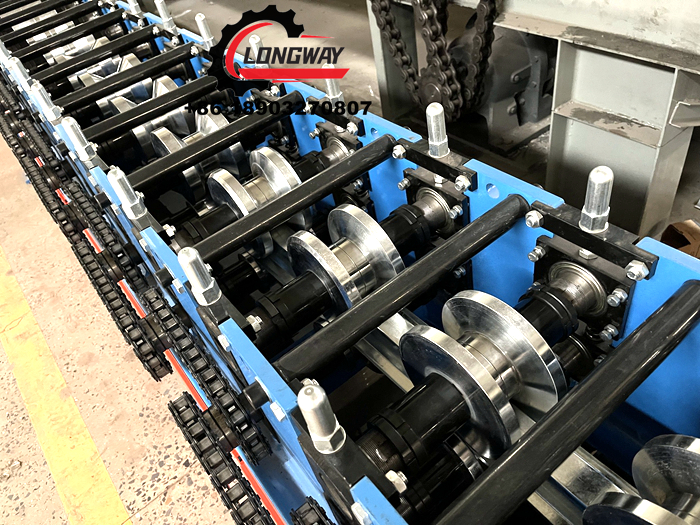

cheap z purlin roll forming machine

Understanding Cheap Z Purlin Roll Forming Machines

In the realm of modern construction and manufacturing, the efficiency and effectiveness of material processing are vital. One of the standout pieces of equipment that meets this demand is the Z purlin roll forming machine. These machines are designed to create Z-shaped purlins, which are crucial components in various structural applications, especially in steel buildings, warehouses, and industrial sites. This article will explore the functionalities, advantages, and factors to consider when seeking affordable Z purlin roll forming machines.

What is a Z Purlin?

Before delving into the machinery itself, it’s important to understand what a Z purlin is. A purlin is a horizontal structural member in a roof or wall that supports the load from the roof covering. The Z shape of the purlin allows it to be interlocked with other steel sections, enhancing the overall structural integrity. This design provides superior strength while minimizing material usage, making it a cost-effective choice for builders.

The Role of Z Purlin Roll Forming Machines

Z purlin roll forming machines are specialized tools used to manufacture these purlins from flat metal sheets. The process involves feeding a flat strip of metal into the machine, which then progressively shapes and cuts it into the desired Z profile. These machines can also be equipped with features that allow for precision cuts, automated adjustment for different sizes, and high production speeds, ensuring that time and labor costs are minimized.

Advantages of Using Z Purlin Roll Forming Machines

1. Cost Efficiency One of the primary advantages of Z purlin roll forming machines is their ability to produce high volumes of material at a lower cost. By minimizing waste and maximizing output, businesses can achieve significant savings.

2. Durability and Quality Machines designed for producing Z purlins ensure that the final product maintains high quality and durability. This durability is crucial for structural applications where safety is paramount.

3. Customization Many roll forming machines offer customizable options, allowing users to create purlins of varying dimensions and thicknesses. This flexibility enables manufacturers to meet specific project requirements efficiently.

cheap z purlin roll forming machine

4. Speed of Production Roll forming machines are known for their high-speed operations. This speed translates to faster turnaround times for projects, allowing businesses to stay competitive in the fast-paced construction industry.

Selecting a Cheap Z Purlin Roll Forming Machine

When considering the purchase of a cheap Z purlin roll forming machine, several factors must be taken into account to ensure that the investment is worthwhile

1. Quality vs. Price While it may be tempting to opt for the cheapest machine available, it is crucial to ensure that quality is not compromised. A low-cost machine that fails to operate efficiently can lead to higher long-term expenses.

2. Manufacturer Reputation Research the manufacturer or supplier of the machine. Look for reviews and testimonials from other customers to gauge their reliability and the efficiency of their machines.

3. Maintenance and Support Consider the availability of maintenance services and customer support. A machine will require ongoing upkeep, and having a support system in place is invaluable.

4. Technology and Features Evaluate the machine’s specifications, such as the thickness of materials it can handle, speed settings, and automation features. Advanced technology may provide better efficiency, even if the initial investment is higher.

5. Warranty and After-sales Service A good warranty can provide peace of mind and protect your investment. Additionally, reliable after-sales service can help alleviate potential issues that may arise during operation.

Conclusion

A cheap Z purlin roll forming machine can be an excellent investment for businesses looking to streamline their production processes while maintaining quality and cost-effectiveness. By understanding the benefits of these machines and carefully assessing options based on quality and support, companies can position themselves for success in an increasingly competitive market. As the construction industry grows and evolves, embracing innovative machinery becomes essential to staying ahead of the curve.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025