Affordable Trapezoidal Sheet Roll Forming Equipment for Efficient Production

The Advantages of Using a Cheap Trapezoidal Sheet Roll Forming Machine

In the ever-evolving world of manufacturing, efficiency and cost-effectiveness are paramount for businesses looking to stay competitive. Among various machines used for metal fabrication, the trapezoidal sheet roll forming machine has gained popularity due to its unique capability to produce trapezoidal sheets used in roofing, siding, and other structural applications. This article will explore the benefits of utilizing a cost-effective trapezoidal sheet roll forming machine.

What is a Trapezoidal Sheet Roll Forming Machine?

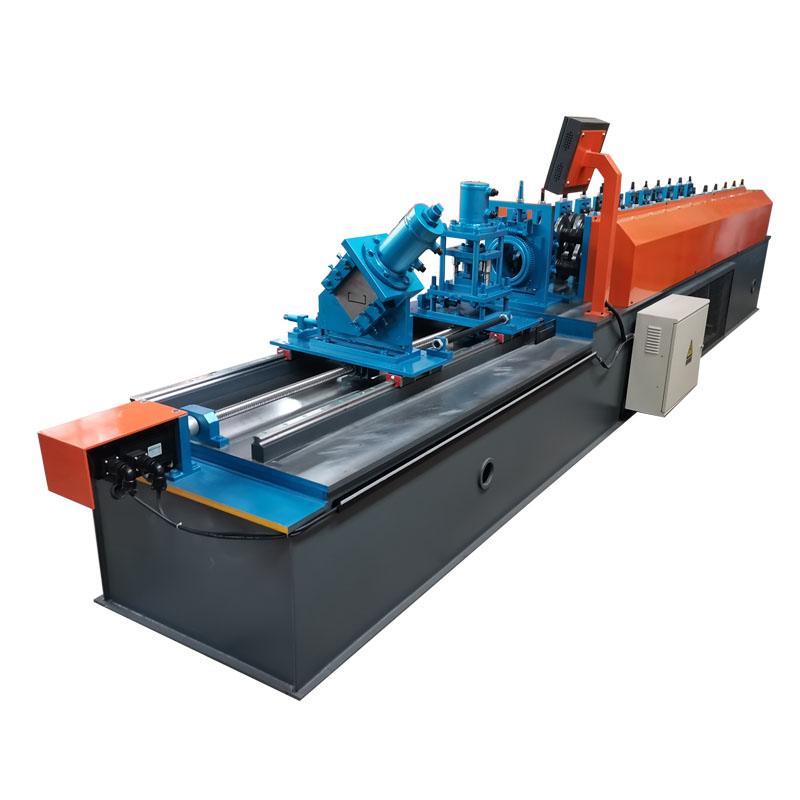

A trapezoidal sheet roll forming machine is a specialized equipment designed to process metal sheets into trapezoidal shapes through a series of rollers. These machines can create sheets with varying thicknesses, widths, and lengths to meet specific project requirements. They are typically used in construction, agriculture, and manufacturing industries for creating durable roofing panels and wall cladding.

Cost-Effectiveness

One of the major advantages of a cheap trapezoidal sheet roll forming machine is its affordability. Lower initial costs make it accessible for small and medium-sized enterprises (SMEs) that seek to invest in their productivity without breaking the bank. This machine enables businesses to generate high-quality trapezoidal sheets at a fraction of the cost compared to traditional manufacturing methods, leading to significant savings over time.

Increased Efficiency

With advancements in technology, modern trapezoidal sheet roll forming machines have significantly improved efficiency and speed. These machines are designed to minimize material wastage and reduce production time by implementing streamlined processes. As a result, manufacturers can increase their output and meet the demands of their customers more effectively. A faster production rate not only enhances profitability but also allows businesses to take on more projects simultaneously.

cheap trapezoidal sheet roll forming machine

Versatility and Customization

A cheap trapezoidal sheet roll forming machine offers remarkable versatility, capable of producing various profiles and sizes of trapezoidal sheets. Customization options allow manufacturers to tailor their products to specific architectural designs and client requirements. This adaptability means that businesses can cater to a broader market, engaging in different projects ranging from residential homes to industrial buildings.

Durability and Quality

Despite being cost-effective, trapezoidal sheets produced by roll forming machines maintain high durability and quality standards. These sheets are typically made from robust materials such as steel or aluminum, which ensures long-lasting performance and resistance to environmental factors. The precision of the roll forming process guarantees that the sheets fit together seamlessly, minimizing the risk of leaks and enhancing the integrity of the structures they protect.

Easy Operation and Maintenance

Most trapezoidal sheet roll forming machines are designed with user-friendliness in mind. Operators can quickly learn to operate the machines, reducing the need for extensive training. Additionally, many models require minimal maintenance, further contributing to their cost-effectiveness.

Conclusion

Investing in a cheap trapezoidal sheet roll forming machine presents numerous advantages for manufacturers seeking to enhance their production capabilities. With cost savings, increased efficiency, versatility, and durable output, this machine can be a game-changer for businesses in various sectors. As the demand for high-quality construction materials continues to rise, employing a trapezoidal sheet roll forming machine may be the strategic decision needed to thrive in today’s competitive market. Whether you are a startup or an established enterprise, the benefits of this equipment are undeniable, making it an essential asset for your manufacturing needs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025