cheap steel roof sheet making machine price

The Cost-Effectiveness of Cheap Steel Roof Sheet Making Machines

In today’s construction industry, the demand for durable and economical building materials is ever-increasing. Among these materials, steel roof sheets have gained popularity due to their strength, longevity, and low maintenance requirements. This has led to an upsurge in the market for machines that manufacture these sheets. If you're considering entering this industry, it's essential to understand the implications of investing in cheap steel roof sheet making machines.

Understanding Steel Roof Sheet Making Machines

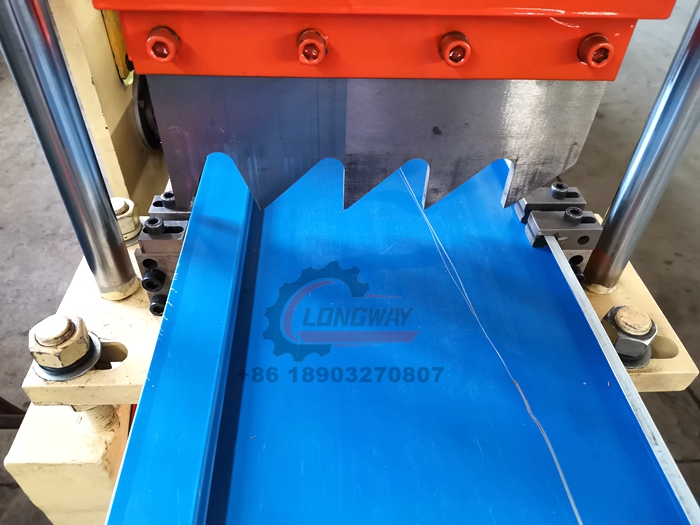

Steel roof sheet making machines are specialized tools designed to produce steel roofing sheets in various sizes, styles, and finishes. These machines can cut and profile sheets from coiled steel, enabling manufacturers to create products suited to different architectural needs. The automation of this process improves efficiency, speeds up production, and helps maintain high-quality standards.

Why Cheap Machines?

When the market offers various options for steel roof sheet making machines, the price variability can be substantial. While investing in a machine that is cheaper may seem appealing, it’s crucial to weigh the benefits against potential downsides. Cheap machines are often designed to lower initial costs but may come with compromises regarding durability, speed, and overall performance.

Factors Influencing Price

1. Material Quality The quality of materials used in constructing the machine will significantly affect its price. High-quality machines made from durable materials tend to have a higher upfront cost but provide better performance and longevity.

cheap steel roof sheet making machine price

2. Technology and Features Advanced machines with automated features such as computer numerical control (CNC), programmable settings, and efficient energy usage might come at a higher price. However, these features can lead to significant savings in labor costs and increased productivity.

3. Manufacturer Reputation Established manufacturers often command higher prices due to their proven track record of quality and service. Conversely, cheaper machines may come from less-known brands or less stringent manufacturing processes, raising concerns about reliability.

4. After-Sales Service Investing in a machine is not just about the initial purchase; ongoing support, maintenance, and availability of spare parts are crucial. Sometimes, cheaper options come with poor after-sales service, leading to higher long-term costs.

The Cost-Benefit Analysis

It's essential to conduct a thorough cost-benefit analysis before making a decision. While a cheap steel roof sheet making machine might seem like a bargain initially, hidden costs can arise from frequent repairs, subpar production quality, and longer operational downtimes. These factors can inflate the overall expenses and affect profitability.

Conclusion

In conclusion, while the allure of cheap steel roof sheet making machines is undeniable, the long-term implications of such an investment need careful consideration. Quality, technology, and manufacturer reliability play pivotal roles in determining the overall value of the machine.

In this competitive industry, having efficient and reliable machines can mean the difference between success and failure. Therefore, it's advisable for prospective buyers to invest wisely, ensuring that the machine they choose aligns with their production goals and financial viability. Investing a bit more upfront for a more durable and efficient machine could ultimately lead to greater savings and enhanced profitability in the long run. Ultimately, careful research and planning will equip you with the knowledge needed to make an informed decision that advantages your business for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025