cheap steel roll forming machine supplier

Exploring Affordable Steel Roll Forming Machine Suppliers

In the construction and manufacturing industries, steel roll forming machines play a vital role in producing a wide array of components, from simple metal sheets to complex structural forms. These machines are essential for fabricating metal parts that are used in roofing, wall panels, and various other constructions. However, the initial investment for such machinery can be quite substantial. For many businesses, especially startups and small enterprises, finding affordable suppliers for steel roll forming machines is of utmost importance. This article delves into the considerations when seeking cheap steel roll forming machine suppliers and the benefits of doing so.

Understanding Steel Roll Forming Machines

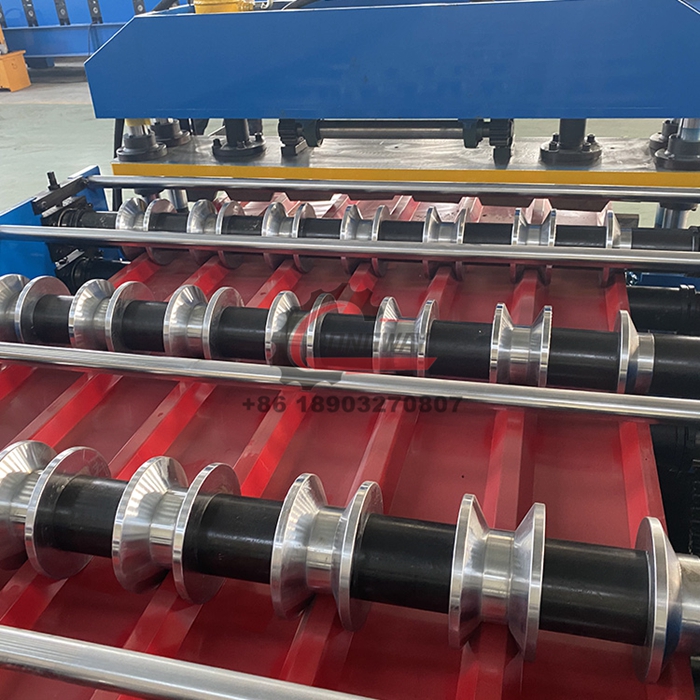

Steel roll forming is a process that involves the continuous bending of steel sheets or strips into desired shapes. The process uses a series of rollers to gradually deform the metal into a specific profile, ensuring precision and efficiency. Typical applications of roll-formed products include HVAC systems, metal building components, and even automotive parts.

Given the importance of these machines, the market has seen a proliferation of suppliers, ranging from large international manufacturers to smaller local companies. However, the challenge lies in finding suppliers that offer high-quality machines at competitive prices.

Factors to Consider When Choosing a Supplier

When looking for affordable steel roll forming machine suppliers, several key factors must be considered

1. Quality of Machinery While price is an essential factor, the quality of the machines should not be compromised. A lower price might result from poor build quality, leading to frequent breakdowns and increased maintenance costs. It’s important to choose suppliers who offer machines that comply with industry standards and provide warranties.

2. Customization Options Different projects may require different machine configurations. Many suppliers offer customization, allowing businesses to tailor machines to their specific needs. Ensure the supplier is willing to work closely with you to create a machine that meets your unique requirements.

3. After-Sales Support Affordable machinery often comes with limited support. It's crucial to choose a supplier that offers reliable after-sales support, including maintenance services, spare parts availability, and operator training. This support can significantly reduce downtime in your operations.

cheap steel roll forming machine supplier

4. Reputation and Reviews Researching supplier reputations is vital. Reading customer reviews and testimonials can provide insights into the reliability and performance of their machines. Consider reaching out to other businesses in the industry to gather recommendations.

5. Delivery and Installation Assess the supplier's ability to deliver and install the machinery within a reasonable timeframe. Delays can impact your project schedules, so ensure that the supplier can meet your deadlines.

Benefits of Choosing Affordable Suppliers

Opting for a cheap steel roll forming machine supplier can offer several advantages, especially for small businesses

1. Cost Savings Lower initial investment allows smaller companies to allocate their resources towards other critical areas, such as marketing and workforce development.

2. Increased Competitiveness By reducing production costs through affordable machinery, companies can price their products more competitively in the market.

3. Investment in Other Technologies With the money saved from purchasing affordable machines, businesses can invest in complementary technologies or equipment to enhance their operations.

4. Adaptability Smaller and more affordable suppliers may provide flexibility in terms of machine sizes and functionalities, allowing businesses to adapt quickly to changing market demands.

Conclusion

In conclusion, finding a cheap steel roll forming machine supplier is a task that requires careful consideration of multiple factors beyond just price. While affordability is crucial, the quality, reputation, and support offered by suppliers are equally important. By conducting thorough research and exploring various options, businesses can find machinery that meets their needs without compromising on quality. This approach not only contributes to operational efficiency but also enhances competitiveness in an ever-evolving market. As the construction and manufacturing sectors continue to grow, investing in the right steel roll forming machines will undoubtedly pay dividends in the long run.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025