cheap silo roll forming machine

Exploring the Benefits of Cheap Silo Roll Forming Machines

In recent years, the demand for cost-effective solutions in manufacturing has surged, particularly in the construction and agricultural sectors. One such innovation is the cheap silo roll forming machine, a technology designed to streamline the production of silos used for grain storage, feed, and other materials. As businesses strive to enhance their efficiency while minimizing costs, these machines are becoming increasingly popular.

Understanding Silo Roll Forming Machines

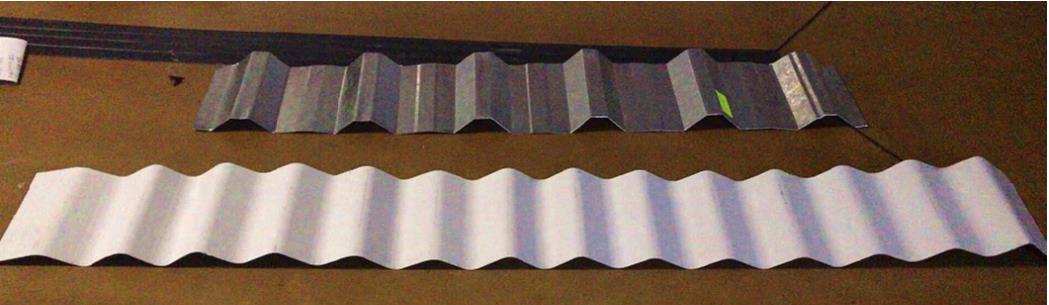

Silo roll forming machines are specialized equipment used to create steel components for silos. The process involves taking a flat strip of metal and continuously feeding it through a series of rollers that gradually shape it into the desired form. By utilizing this method, manufacturers can produce high-quality silo panels that are not only robust but also lightweight—a crucial factor for ease of transportation and installation.

Cost-Effectiveness of Cheap Silo Roll Forming Machines

The term cheap in relation to silo roll forming machines typically refers to their affordability without compromising quality. These machines have been designed to meet the needs of small to medium-sized enterprises (SMEs) that might not have the budget to invest in high-end equipment. By choosing a cost-effective solution, businesses can greatly reduce their upfront investment and operational costs while still achieving the required output.

Moreover, the operational efficiency of these machines significantly lowers production costs. They require less labor due to their automated processes, and the precision with which they operate minimizes material waste. This means that companies can enjoy a higher profit margin while delivering quality products to their clients.

cheap silo roll forming machine

Flexibility and Customization

Another advantage of cheap silo roll forming machines is their flexibility. Many of these machines are designed to accommodate various sizes and shapes of silos, allowing manufacturers to customize their production according to client specifications. This flexibility is essential, especially in industries where the demand for different silo types can fluctuate.

Furthermore, some manufacturers offer a range of roll forming machines that can be adapted for various other applications beyond silo production, enhancing the value of the investment. By diversifying their capabilities, companies can tap into new markets and increase their revenue potential.

Durability and Longevity

Investing in a cheap silo roll forming machine does not imply sacrificing quality. Many of these machines are built with durable materials designed to withstand prolonged use. Their longevity ensures that businesses can continue to rely on their equipment for years without the need for frequent replacements or repairs, which further contributes to cost savings in the long run.

Conclusion

In conclusion, cheap silo roll forming machines represent an intelligent investment for companies looking to optimize their production processes while keeping costs low. Their affordability, combined with high operational efficiency, flexibility, and durability, makes them an attractive option for businesses in the construction and agricultural sectors. As the demand for efficient, cost-effective manufacturing solutions continues to grow, the adoption of cheap silo roll forming machines is likely to increase, offering a competitive edge to those who embrace this technology. By incorporating these machines into their operations, businesses can not only improve their bottom line but also enhance their capability to serve their customers more effectively.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025