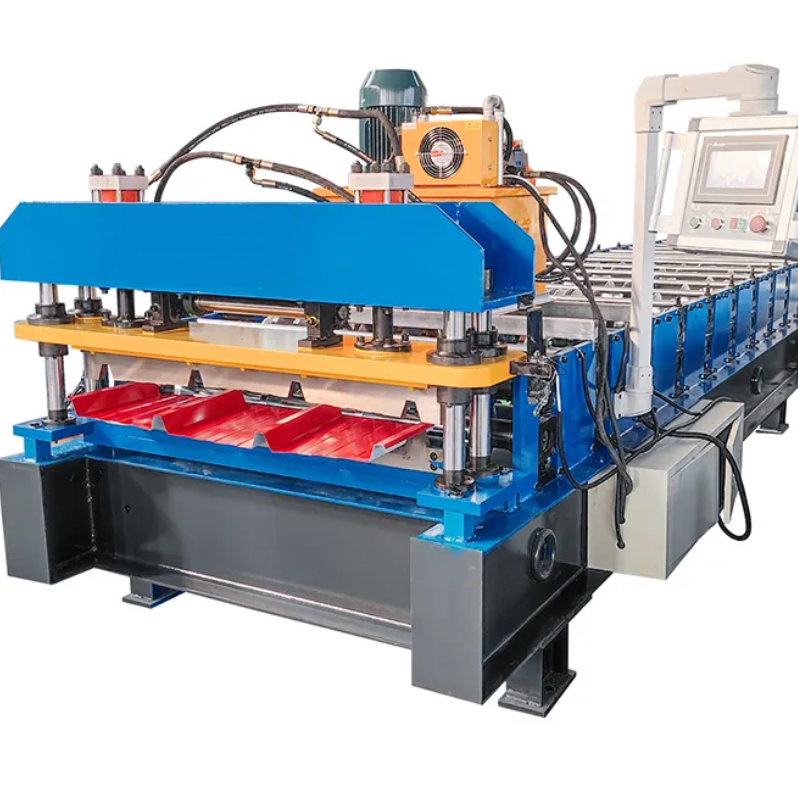

Affordable Sheet Metal Roll Forming Equipment for Efficient Production

Understanding Cheap Sheet Metal Roll Forming Machines

In today’s manufacturing landscape, the demand for efficient and cost-effective production methods is paramount. One of the innovative solutions that has emerged is the use of cheap sheet metal roll forming machines. These machines are designed to reshape sheet metal into precise profiles, meeting the specific needs of various industries while optimizing costs.

What is Roll Forming?

Roll forming is a continuous bending process in which a long strip of metal is passed through a series of rollers. Each roller gradually bends the metal into the desired shape. This method is particularly beneficial for producing complex cross-sections in a consistent and efficient manner. When applied to sheet metal, roll forming machines can create a wide variety of products, including roofing panels, steel framing, and automotive components.

The Advantages of Affordable Roll Forming Machines

1. Cost Efficiency As the name suggests, cheap sheet metal roll forming machines provide an economical option for manufacturers looking to reduce operational costs. They offer a lower initial investment compared to more advanced systems while still providing reliable performance.

2. Speed and Efficiency These machines are designed for high-speed production. Once set up, they can produce large quantities of parts in a relatively short amount of time, significantly increasing the throughput of manufacturing processes.

3. Consistency and Precision One of the key benefits of using roll forming machines is their ability to deliver consistent results. The automation of the process minimizes human error, ensuring that each piece produced meets the precise specifications required. This consistency is crucial in industries such as automotive, where tolerances can be tight.

4. Versatility Cheap sheet metal roll forming machines are adaptable to produce a wide range of profiles and materials. Whether it’s aluminum, steel, or other metals, these machines can be tailored to suit diverse manufacturing needs. Furthermore, they can handle different thicknesses of sheet metal, making them valuable in various applications.

cheap sheet metal roll forming machines

5. Reduced Waste Roll forming is a highly efficient process that generates minimal scrap. The continuous nature of the method allows for better material utilization, ultimately resulting in lower raw material costs and reduced environmental impact.

Considerations When Choosing a Cheap Roll Forming Machine

While the affordability of these machines is appealing, there are several factors to keep in mind

- Quality of Construction It’s crucial to ensure that the machine is built from high-quality materials. Cheaper options may compromise on structural integrity, leading to maintenance issues down the line.

- Support and Service When purchasing a roll forming machine, consider the manufacturer’s reputation for customer service and support. Having access to technical assistance and spare parts can make a significant difference in the longevity of your investment.

- Customization Options Depending on your specific needs, you may require customization of the machine. It's important to choose a manufacturer that offers flexible design options to accommodate unique requirements.

Conclusion

Cheap sheet metal roll forming machines represent a valuable investment for manufacturers seeking to enhance production efficiency without breaking the bank. Their cost effectiveness, coupled with high-speed production, precision, and adaptability, makes them an attractive option in today’s competitive manufacturing environment. However, potential buyers should conduct thorough research to ensure they choose a reliable machine that meets their operational demands. By investing in the right equipment, businesses can significantly improve their manufacturing processes and drive growth.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025