cheap r panel roll former

Understanding the Benefits of Cheap R Panel Roll Formers

In the construction and manufacturing industries, the demand for efficient and cost-effective solutions is ever-growing. One emerging technology that has been gaining popularity is the roll forming process, particularly for R panel production. R panels are widely used in roofing, siding, and other applications due to their durability and aesthetic appeal. With the advent of affordable roll forming machines, manufacturers can now produce R panels at a lower cost without compromising on quality.

What is a Roll Former?

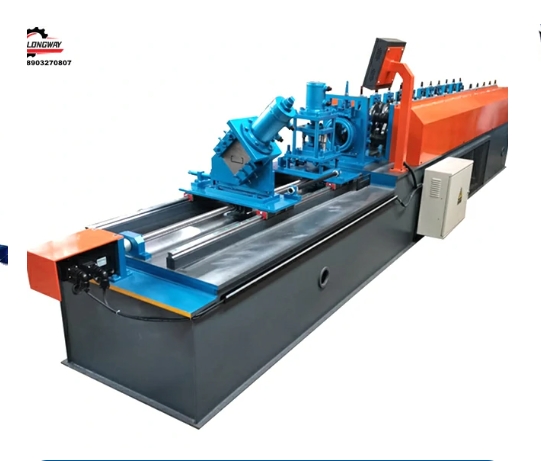

A roll former is a machine used to create continuous profiles from metal sheets. The material is fed through a series of rollers, each set designed to incrementally shape the metal into a desired profile. For R panels, the roll forming machine is specifically designed to create the unique ribbed pattern that provides both strength and visual appeal.

Advantages of Cheap R Panel Roll Formers

1. Cost Efficiency The primary advantage of cheap R panel roll formers is the reduced capital investment required to start manufacturing. With advancements in technology, manufacturers now have access to affordable machines that deliver similar performance to more expensive models. This reduction in initial cost can significantly lower the barriers to entry for small-scale manufacturers or startups.

2. Fast Production Rates Modern roll formers are capable of producing R panels at impressive speeds. This efficiency means businesses can meet customer demands more quickly, improving overall productivity and decreasing lead times. With the low-cost entry, manufacturers can afford to scale production to optimize their workflow.

cheap r panel roll former

3. Quality and Strength Even at a lower price point, many cheap R panel roll formers are designed to produce high-quality panels. These machines are engineered to maintain tight tolerances and produce panels that meet industry standards for thickness and strength. As a result, manufacturers can ensure that their R panels are both durable and reliable.

4. Customization Options Despite their affordability, many cheap roll formers offer a range of customization options. This feature allows manufacturers to create panels in various sizes, colors, and profiles based on consumer demand. Customization is a key factor in distinguishing products in a competitive market, providing businesses with a competitive edge.

5. Reduction in Waste Using a roll forming machine can help reduce material waste significantly. The continuous process allows for efficient use of metal sheets, minimizing scrap. This not only saves money but also supports environmentally friendly practices, which are increasingly important in today’s market.

6. Ease of Operation and Maintenance Affordable R panel roll formers are often designed with user-friendly controls and straightforward maintenance requirements. This feature makes it easier for manufacturers to train workers and maintain production levels without requiring specialized skills. Additionally, the simplicity of upkeep helps reduce downtime and prolongs the life of the equipment.

Conclusion

In summary, the introduction of cheap R panel roll formers has revolutionized the way manufacturers approach metal panel production. With their cost efficiency, rapid production capabilities, and customizable features, these machines are becoming indispensable tools in the construction industry. As the demand for R panels continues to grow, investing in an affordable roll former may provide the key to success for many businesses. Whether you are a small startup or an established manufacturer, now is the perfect time to explore the benefits of incorporating cheap R panel roll formers into your operations. Not only can they enhance your production capabilities, but they can also position your business to thrive in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025