cheap roof tile roll forming machine

Understanding the Cheap Roof Tile Roll Forming Machine

In recent years, the construction industry has seen a significant shift towards efficiency and cost-effectiveness. Among the innovations that have emerged, the roof tile roll forming machine stands out as a vital tool for manufacturers and builders alike. This technology allows for the mass production of high-quality roofing tiles while minimizing waste and labor costs. One of the most appealing aspects of this machinery is the availability of affordable or cheap options, which make it accessible to a broader range of businesses.

What is a Roof Tile Roll Forming Machine?

A roof tile roll forming machine is an industrial device designed to transform metal sheets into interlocking roof tiles. The process involves feeding a flat metal sheet into the machine, where it is molded and cut into the desired shape through a series of rollers. The end product is a lightweight, durable roofing solution that can be coated with various finishes to enhance its aesthetic appeal and weather resistance.

The Advantages of Using a Roof Tile Roll Forming Machine

1. Cost Efficiency The main draw of a cheap roof tile roll forming machine is its affordability. While high-end models can be a significant investment, many manufacturers have developed cost-effective alternatives that still deliver excellent performance. These machines allow companies to produce roofing materials at a fraction of the cost compared to traditional methods.

2. Quality and Durability Although they are marketed as cheap, many roll forming machines are designed to produce high-quality tiles that rival more expensive options. By carefully selecting the materials and employing advanced production techniques, manufacturers can consistently create tiles that meet industry standards for durability and longevity.

3. Customization Modern roll forming machines offer customization options that cater to varying design preferences. Business owners can adjust the machine settings to create different tile profiles, colors, and finishes, enabling them to meet the specific needs of their clients without incurring additional costs.

4. Efficiency and Speed The automated nature of roll forming machinery results in reduced labor requirements and increased production speeds. This efficiency not only cuts operational costs but also allows manufacturers to respond quickly to market demands. Whether it’s for residential or commercial projects, the ability to produce tiles in bulk ensures that builders have the materials they need when they need them.

cheap roof tile roll forming machine

5. Reduced Waste Traditional roofing tile production often leads to significant material waste. In contrast, roll forming minimizes waste by using specific measurements and efficient cutting techniques. The precise nature of the machine reduces off-cuts and surplus materials, leading to a more sustainable production process.

Considerations When Purchasing a Cheap Roof Tile Roll Forming Machine

Despite the enticing affordability of cheap machines, prospective buyers should consider several factors before making a purchase

1. Quality Assurance Research the manufacturer’s reputation and the warranties offered. A low price should not come at the expense of quality. Look for reviews and testimonials to gauge the reliability of the machine.

2. Post-Purchase Support Ensure that the manufacturer provides adequate support and maintenance services. Given that machinery can require repairs or replacement parts, a good support system is crucial for long-term success.

3. Training and Usability Consider the ease of operation. Some machines may require specialized training to operate effectively. Investing time in learning how to use the equipment efficiently can enhance productivity and minimize errors.

4. Scalability If you anticipate growth in your business, choose a machine that can be upgraded or expanded upon in the future. This adaptability can save costs as your production needs increase.

Conclusion

The cheap roof tile roll forming machine is a game-changer for businesses in the roofing and construction industry. By offering an affordable solution that does not compromise on quality, these machines enable manufacturers to produce durable and aesthetically pleasing roofing tiles efficiently. As the demand for cost-effective and environmentally friendly building materials continues to rise, investing in such technology can position businesses for long-term success in a competitive marketplace. Whether for new construction or renovation projects, a roof tile roll forming machine is an invaluable asset that can enhance both productivity and profitability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

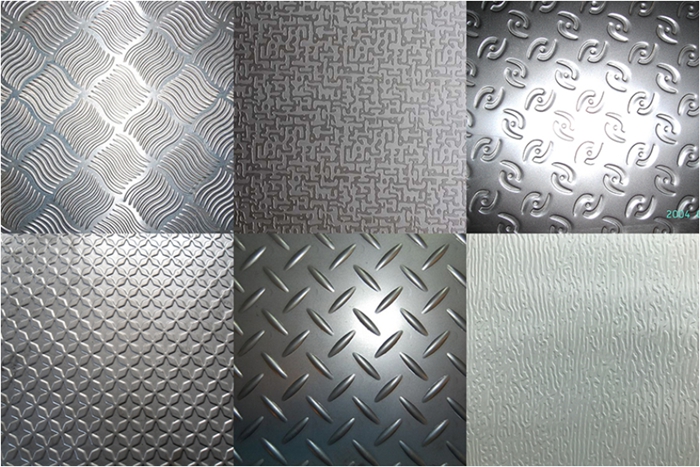

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025