cheap roof panel forming machine

The Importance of a Cheap Roof Panel Forming Machine

In today's construction industry, efficiency and cost-effectiveness have become paramount. As building projects evolve, the demand for versatile and affordable solutions continues to grow. One crucial piece of equipment that meets these demands is the roof panel forming machine. Particularly, the emphasis on cheap roof panel forming machines highlights a rising trend towards budget-friendly manufacturing options without compromising on quality.

What is a Roof Panel Forming Machine?

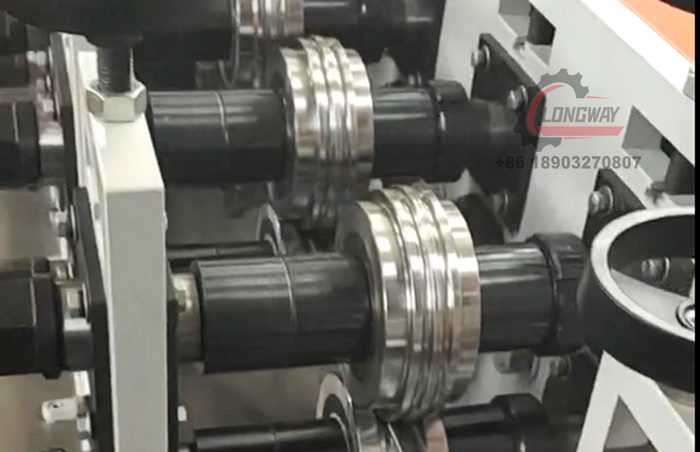

A roof panel forming machine is specialized equipment designed to produce roofing panels in various shapes, sizes, and materials. These machines can form panels from materials like galvanized steel, aluminum, and stainless steel, enabling the production of roofing sheets that are both durable and aesthetically appealing. Roof panel forming machines come in various configurations, ranging from manual to fully automated, catering to different operational scales and requirements.

Benefits of Purchasing a Cheap Roof Panel Forming Machine

1. Cost Savings The most obvious advantage of opting for a cheap roof panel forming machine is the significant cost savings. In an industry where margins can be thin, having an affordable machine helps reduce overhead costs. This allows both small businesses and larger contractors to increase profitability.

2. Increased Production Efficiency Many cheap roof panel forming machines are designed for high-speed production. With the ability to produce thousands of panels in a fraction of the time it would take manually, these machines enhance productivity. This efficiency allows companies to take on more projects and meet tighter deadlines, thereby expanding their market reach.

3. Versatility in Designs Modern roof panel forming machines can produce various panel designs, from standing seam roofs to corrugated sheets. This versatility equips manufacturing businesses with the ability to cater to diverse customer needs, enabling them to remain competitive in the market.

4. Reduced Material Waste Advanced forming technology reduces material wastage during the production process. By precisely cutting and shaping materials, these machines maximize usage, allowing businesses to save on raw materials and minimize environmental impact.

cheap roof panel forming machine

5. Ease of Operation Most affordable roof panel forming machines are designed with user-friendly controls, making them accessible for operators of varying skill levels. Some machines come with automatic systems and intuitive interfaces, reducing the need for extensive training and ensuring smooth operation.

Choosing the Right Cheap Roof Panel Forming Machine

When looking for a cheap roof panel forming machine, a few critical factors should be considered

- Quality and Durability While affordability is a priority, it is essential not to sacrifice quality. Research manufacturers and customer reviews to ensure that the machine operates effectively and lasts for years.

- Production Capacity Determine the production volume required for your projects. Machines come in various sizes and capacities, so selecting one that aligns with your needs is crucial.

- Types of Panels Ensure that the machine can produce the specific types of panels required for your projects. Different designs may require specialized machines.

- Customer Support and Warranty Check the manufacturer's support options, warranty policies, and availability of spare parts. Good customer service can be invaluable if any issues arise.

Conclusion

In the fast-paced construction landscape, a cheap roof panel forming machine emerges as a smart investment for businesses looking to streamline operations and reduce costs. By understanding the benefits and importance of selecting the right machine, companies can enhance their productivity and ultimately improve their bottom lines. As technology continues to advance, these machines will play a vital role in shaping the future of roofing construction, making quality and affordability more accessible than ever.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025