Affordable Roll Forming Equipment for Cost-Effective Manufacturing Solutions

The Advantages of Cheap Roll Forming Machines

In the fast-evolving world of manufacturing, efficiency and cost-effectiveness are paramount. One of the most versatile tools in modern metalworking is the roll forming machine. For businesses looking to streamline production while maintaining quality, cheap roll forming machines present an appealing option. These machines offer several advantages, making them an excellent investment for various industries.

First and foremost, cost efficiency is a significant benefit of purchasing a cheap roll forming machine. Traditional metal fabrication methods can be labor-intensive and expensive. Roll forming not only simplifies the process but also reduces overall production costs. Companies can produce complex shapes and profiles with less material waste and in less time, leading to increased profitability.

Moreover, affordability doesn’t mean compromising on quality. Many manufacturers have refined their designs and technology, allowing even low-cost roll forming machines to deliver high precision and durability. These machines are capable of producing consistent, high-quality pieces that meet industry standards. Buyers can find models that offer features such as adjustable speeds and automated controls, ensuring versatility in production.

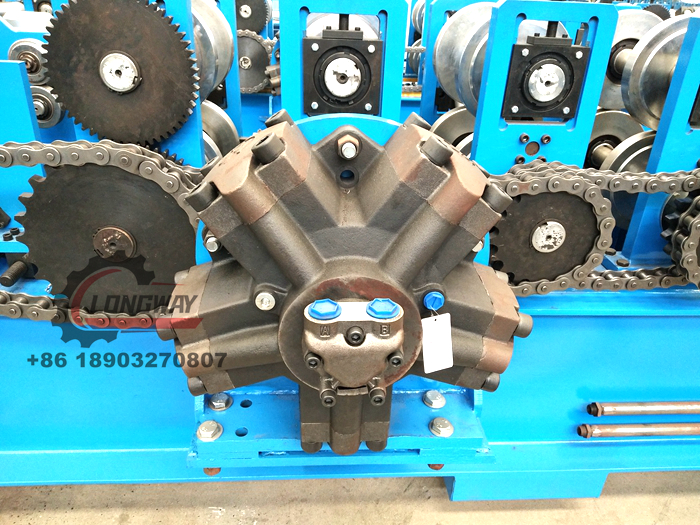

cheap roll forming machine

Another advantage of investing in a cheap roll forming machine is the ease of operation. Modern machines often come equipped with user-friendly interfaces and require minimal training for operators. This translates to reduced workforce training costs and a quicker ramp-up time for production. Additionally, many machines are designed for maintenance efficiency, allowing for quick repairs and minimal downtime.

In terms of applications, cheap roll forming machines can be utilized across various sectors, from construction to automotive. They are ideal for producing components such as roofing sheets, wall panels, and other structural elements. The capacity to customize profiles based on specific needs further enhances their appeal, allowing manufacturers to cater to diverse market demands.

Lastly, the scalability of roll forming technology means that businesses can grow without the need for substantial re-investment in machinery. As production needs increase, companies can easily upgrade or expand their roll forming lines, ensuring that they remain competitive in the market.

In conclusion, cheap roll forming machines offer a blend of cost efficiency, high quality, ease of use, and flexibility that makes them an attractive choice for manufacturers. By adopting this technology, businesses not only enhance their production capabilities but also position themselves for future growth in a competitive landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025