cheap precision rollformers

The Rise of Cheap Precision Rollformers Transforming the Manufacturing Landscape

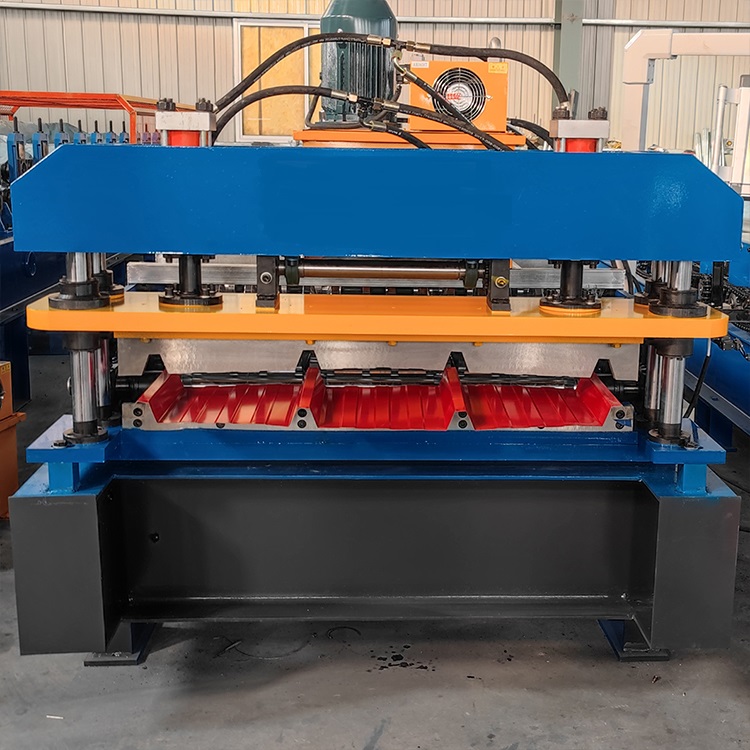

In the ever-evolving manufacturing sector, precision engineering has taken center stage, allowing companies to produce highly accurate and intricately designed components. Among the innovations driving this trend are rollformers, particularly cheap precision rollformers that democratize access to advanced manufacturing technologies. These machines have transformed the production processes across a variety of industries, including automotive, construction, and aerospace, by providing cost-effective solutions without compromising quality.

Understanding Rollforming Technology

Rollforming is a continuous bending operation in which a long strip of metal is passed through a series of rollers. These rollers progressively shape the metal into specific profiles needed for various applications. Precision rollformers are designed to create parts with high accuracy and repeatability, making them indispensable in manufacturing environments where tolerances are tight. Cheap precision rollformers have made this technology accessible to a wider range of businesses, including small and medium enterprises (SMEs) that were previously unable to invest in expensive machinery.

Economic Accessibility

Historically, the cost of high-quality rollforming equipment was a significant barrier for many manufacturers. However, advancements in technology and increased competition among manufacturers have led to the development of more affordable rollformers that maintain precision. Cheap precision rollformers typically feature robust construction, user-friendly controls, and low operational costs. This accessibility allows SMEs to leverage sophisticated manufacturing processes, enhancing their productivity and competitiveness.

Quality without Compromise

The term cheap in the context of precision rollformers may suggest a decrease in quality, but this is often not the case. Manufacturers of cheap precision rollformers recognize the need to balance affordability with performance. Many of these machines utilize advanced materials and innovative engineering designs to ensure they deliver high levels of precision over extended periods. As a result, businesses can achieve high-quality outputs while managing their budgets effectively.

cheap precision rollformers

Versatility and Customization

One of the standout features of cheap precision rollformers is their versatility. These machines can be customized to produce a wide range of profiles and components, adapting to the specific needs of various industries. Whether it’s creating components for roof systems, gutters, or even intricate automotive parts, a precision rollformer can be tailored to meet the required specifications. This flexibility enables manufacturers to diversify their product offerings and respond quickly to market demands.

Environmental Benefits

In addition to their economic advantages, cheap precision rollformers can contribute to more sustainable manufacturing practices. By optimizing material usage and reducing waste, these machines help companies lower their environmental footprint. Efficient rollforming processes generate fewer scrap materials compared to traditional manufacturing methods, aligning with global efforts to promote sustainability in industry.

Future Trends

The landscape of manufacturing will continue to evolve, and the demand for affordable precision engineering solutions is likely to grow. As technologies advance, we can expect the development of even more sophisticated cheap precision rollformers that leverage AI, automation, and IoT (Internet of Things) capabilities. These enhancements will not only improve efficiency but also facilitate data-driven decision-making, leading to smarter manufacturing processes.

Conclusion

The advent of cheap precision rollformers marks a significant shift in the manufacturing landscape. By making advanced rollforming technology accessible to a broader range of businesses, these machines empower SMEs to achieve high-quality production without breaking the bank. As the industry moves towards more sustainable practices and embraces new technologies, the role of affordable precision manufacturing solutions will become increasingly vital. In a competitive global market, the ability to produce precise, high-quality components efficiently is a key factor for success, and cheap precision rollformers are at the forefront of this transformation.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025