cheap portable standing seam roll forming machine

Affordable Portable Standing Seam Roll Forming Machines Revolutionizing the Metal Building Industry

In the construction and manufacturing industries, efficiency and precision are paramount. With the recent advancements in technology, the demand for innovative solutions has led to the development of affordable portable standing seam roll forming machines. This article delves into what these machines are, their benefits, and why they are becoming a crucial tool for metal construction projects.

Understanding Standing Seam Roofs

Standing seam roofs have gained popularity due to their durability, aesthetics, and ability to withstand harsh weather conditions. This roofing style features raised seams that interlock the panels, creating a waterproof barrier. Traditionally, the installation of these roofs required extensive labor and specialized equipment, making it a time-consuming and often expensive process. However, portable standing seam roll forming machines have changed the game by providing a more efficient method for fabricating and installing metal roofing systems.

What Are Portable Standing Seam Roll Forming Machines?

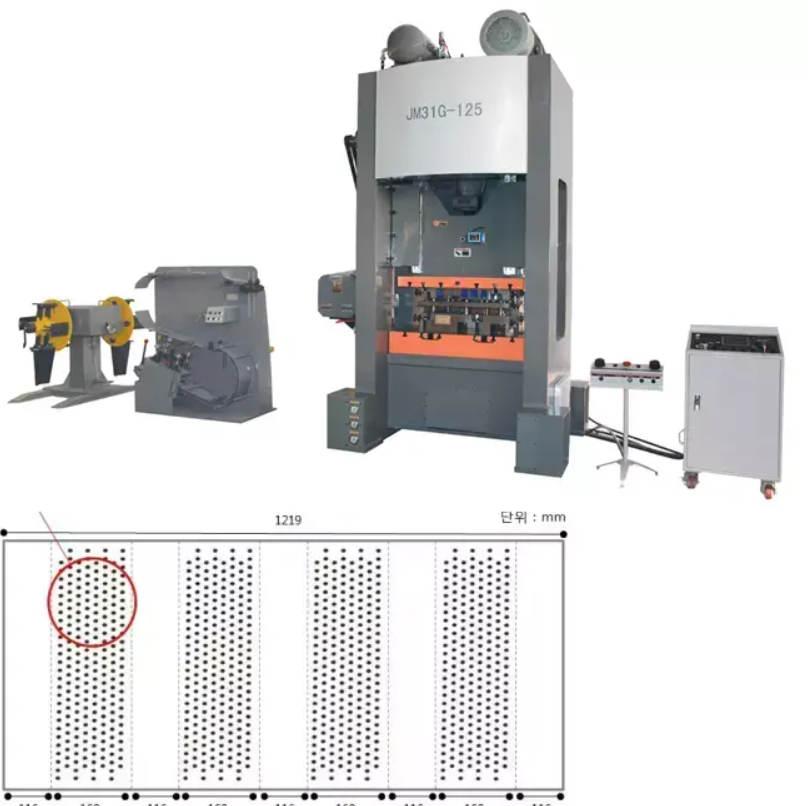

Portable standing seam roll forming machines are specialized tools designed to produce standing seam metal roofing panels on-site. These machines can be transported easily, allowing contractors to bring production directly to the job site. They work by feeding metal coils into the machine, which then shapes the material into the desired standing seam profile. The ability to manufacture roofing panels on-site reduces waste, lowers transportation costs, and accelerates the installation process.

Key Benefits of Using Portable Standing Seam Roll Forming Machines

1. Cost-Effectiveness One of the primary advantages of using affordable portable standing seam roll forming machines is cost savings. By producing panels on-site, contractors can significantly reduce material waste and transportation expenses. Additionally, the fast production time means labor costs are lowered, making it a viable option for budget-conscious projects.

cheap portable standing seam roll forming machine

2. Efficiency and Speed Time is always of the essence in construction, and portable standing seam roll forming machines are designed to be quick and efficient. They can produce a continuous length of roofing panels, reducing the time spent on installation. This streamlined process allows construction projects to stay on schedule and meet deadlines.

3. High Precision These machines offer exceptional precision in panel manufacturing. With advanced technology and digital controls, portable roll forming machines ensure that each panel is accurately shaped and sized to fit the specifications of the project. This precision minimizes the need for adjustments later, saving time and materials.

4. Versatility Portable standing seam roll forming machines are highly versatile. They can be configured to produce various profiles and shapes, accommodating different project requirements. This adaptability makes them suitable for residential, commercial, and industrial applications alike.

5. On-Site Customization Another significant advantage is the ability to customize panels on-site. If a project requires last-minute changes or specific measurements, contractors can quickly adjust the machine to create panels that fit precisely. This flexibility is invaluable for ensuring the final product meets the client’s expectations.

6. Reduced Transportation Risks Transporting metal panels can be fraught with risks, including damage during transit. By fabricating panels on-site, the risk of transportation-related issues is minimized. This leads to a more reliable supply chain and better project outcomes.

Conclusion

Affordable portable standing seam roll forming machines are transforming the landscape of the metal construction industry. Their cost-effectiveness, efficiency, precision, versatility, and on-site customization capabilities make them an essential tool for contractors. As the demand for quality metal roofing continues to grow, investing in these machines not only improves operational efficiency but also enhances the overall quality of construction projects.

In a competitive industry where time and money are critical, portable standing seam roll forming machines present a reliable solution for meeting the challenges of modern construction. By embracing this technology, companies can ensure they remain at the forefront of the industry, ready to tackle any roofing project with confidence and ease.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025