Affordable PBR Roll Forming Solutions for Cost-Effective Construction Projects

The Advantages of Using Cheap PBR Roll Formers in Construction

In the ever-evolving world of construction, efficiency and cost-effectiveness play crucial roles in project success. One of the latest innovations that is transforming the construction industry is the use of roll forming technology, particularly PBR (Purlin Bearing Rib) roll formers. For contractors and builders looking to keep their expenses down without compromising on quality, cheap PBR roll formers are a game-changer. This article discusses their benefits, functionalities, and key considerations when choosing a roll former for your projects.

What is a PBR Roll Former?

PBR roll formers are specialized machines designed to produce PBR metal panels, widely used in roofing and wall applications. These panels have several benefits, including their strength, durability, and resistance to harsh weather conditions. The process of roll forming involves continuously feeding metal sheets through a series of rollers that shape them into the desired profile, offering high precision and consistency in production.

Cost-Effectiveness

One of the primary advantages of utilizing cheap PBR roll formers is their affordability. Investing in this equipment can significantly reduce material costs and labor expenses over time. With a cheap PBR roll former, small- to medium-sized construction companies can produce PBR panels in-house rather than relying on external suppliers, leading to better control over quality and production schedules.

By lowering the cost of metal panels, contractors can offer more competitive pricing to their clients, potentially winning more jobs and increasing their market share. Furthermore, efficient material usage minimizes waste, which is another critical factor in keeping overall project costs down.

Increased Efficiency

PBR roll formers allow for rapid production of metal panels. As the construction industry faces increasing demands for quick turnaround times, having a roll former on-site can facilitate efficient fabrication. Once the machine is set up, it can produce a significant volume of panels in a short period, accelerating the overall construction timeline.

Moreover, PBR roll formers can run on various materials, including steel and aluminum, making them versatile for different types of projects. This adaptability allows contractors to respond quickly to varied requirements, ensuring that they can meet clients' specifications without delay.

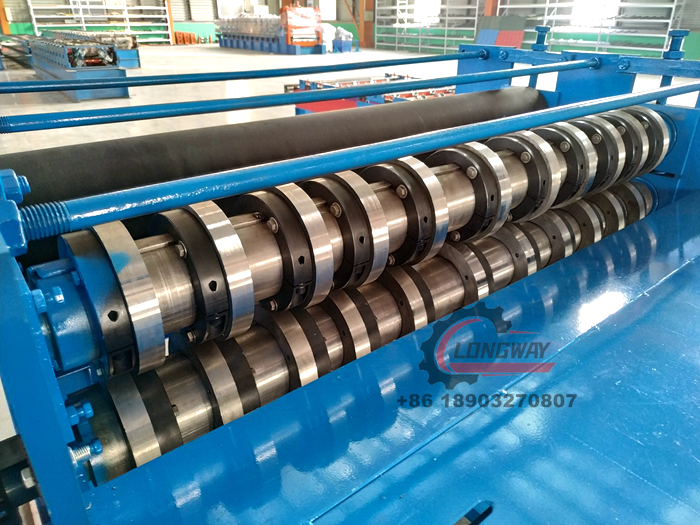

cheap pbr roll former

Consistent Quality

Cheap does not have to mean compromised quality. Modern PBR roll formers are built with precision engineering that guarantees consistent quality across all produced panels. The roll forming process ensures that each panel adheres to specified tolerances, which is vital for structural integrity and aesthetic appeal.

Consistency in production reduces the risk of defects and the need for costly rework, contributing to a smoother workflow and enhanced satisfaction for both contractors and clients. Additionally, the durability of PBR panels, made possible through the roll forming process, ensures that the end product can withstand the test of time and harsh environmental conditions.

Key Considerations When Purchasing

When considering the purchase of a cheap PBR roll former, several factors should be evaluated. First, assess the machine’s capabilities, including its speed, size, and the types of materials it can handle. A good roll former should accommodate specific project needs and allow for future scalability.

Secondly, consider the manufacturer's reputation and after-sales support. Reliable support is crucial for ensuring minimal downtime and maintenance issues, keeping your operations running smoothly.

Lastly, factor in the initial investment and potential return on investment (ROI). While a cheap roll former may seem appealing, ensure that it does not compromise on the essential features required for your production needs.

Conclusion

In conclusion, cheap PBR roll formers represent an excellent opportunity for construction professionals aiming to reduce costs without sacrificing quality. By investing in this technology, contractors can enhance their efficiency, produce consistent and high-quality components, and deliver projects on time. As the construction industry continues to grow, embracing affordable yet effective solutions like PBR roll formers will be vital for success. Whether you're a small contractor or part of a larger operation, integrating this technology can pave the way for increased profitability and competitiveness in your field.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025