Affordable PBR Roll Forming Machines for Cost-Effective Construction Solutions

Exploring the Benefits of Cheap PBR Roll Formers in Modern Manufacturing

In the world of modern construction and manufacturing, the demand for efficient, cost-effective, and versatile machines has never been higher. Among these machines, the PBR (Panel Bending Roll) roll former has emerged as a significant player, particularly in the production of metal panels. This article delves into the advantages of cheap PBR roll formers, their applications, and why they are becoming increasingly relevant in today’s market.

What is a PBR Roll Former?

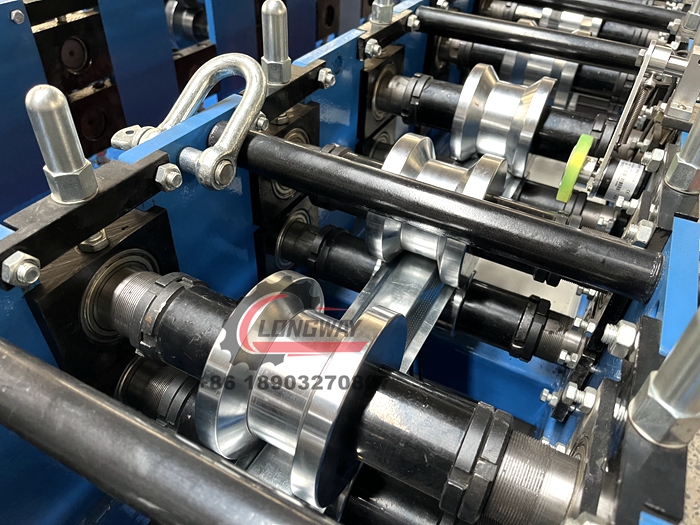

A PBR roll former is a specialized machine designed to create PBR panels, which are commonly used as roofing and siding materials in commercial and industrial buildings. These panels are known for their durability, ease of installation, and efficient water drainage capabilities. The roll forming process entails feeding flat metal sheets through a series of rollers which gradually shape the metal into the desired profile without cutting or machining, making it extremely efficient and cost-effective.

Cost-Effectiveness of Cheap PBR Roll Formers

One of the most appealing aspects of cheap PBR roll formers is their affordability. These machines provide a high return on investment for small businesses and large manufacturers alike. The cost savings are realized not just in the initial purchase, but also in the long-term operational efficiencies they offer. Some of the key cost-effective benefits include

1. Reduced Labor Costs The automation provided by roll formers minimizes the need for manual labor. Once set up, these machines can operate continuously, producing large quantities of panels with little human intervention.

2. Material Efficiency PBR roll formers are designed to maximize material usage. The continuous feed of metal is shaped into panels with minimal waste, allowing manufacturers to get the most out of their raw materials.

3. Lower Energy Consumption Many cheap PBR roll formers are designed to be energy efficient. Compared to traditional manufacturing methods, these machines consume less power, reducing overall operational costs.

Versatility and Customization

cheap pbr roll former

Cheap PBR roll formers are not only cost-effective but also incredibly versatile. They can be customized to produce various panel sizes and profiles, accommodating a wide range of construction needs. This flexibility is essential in today’s market, where design specifications and regulatory requirements can vary dramatically. Manufacturers can adapt their PBR roll formers to produce panels with different thicknesses, coatings, and finishes, meeting the specific needs of their clients.

Additionally, with advancements in technology, many roll formers can now integrate digital controls, allowing operators to adjust settings and monitor production in real-time. This adaptability means that businesses can respond quickly to market trends and customer demands, further enhancing their competitive edge.

Enhancing Production Speed

Another significant advantage of investing in a cheap PBR roll former is the speed at which it can produce high-quality panels. The roll forming process is inherently faster than traditional metalworking techniques, allowing manufacturers to meet tight deadlines without compromising on quality. With efficient operation, manufacturers can increase their output significantly, capturing a larger market share and improving their overall profitability.

Applications Across Industries

The application of PBR panels extends beyond just roofing and siding. Industries such as agriculture, warehousing, and manufacturing utilize these materials for various purposes, including

- Storage Facilities PBR panels are ideal for constructing storage buildings due to their strength and resistance to weathering. - Agricultural Structures Farms often utilize PBR panels for barns and storage units, benefiting from their low maintenance and durability. - Industrial Buildings Many industrial facilities prefer PBR panels for their efficient installation and long lifespan, optimizing operational efficiencies.

Conclusion

In conclusion, cheap PBR roll formers present a unique opportunity for businesses looking to streamline their manufacturing processes while maintaining cost-efficiency. Their versatility, speed, and adaptability make them an invaluable asset in the ever-evolving construction and manufacturing landscapes. As the demand for high-quality metal panels continues to rise, investing in a cheap PBR roll former could very well be the key to sustaining growth and enhancing competitiveness in today’s market. Embracing these machines and their capabilities positions manufacturers to thrive in an increasingly cost-sensitive environment, ensuring they can meet customer needs while optimizing their production processes.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025