Affordable Metal Wall Panel Production Equipment for Efficient Manufacturing Solutions

Exploring the Benefits and Features of Cheap Metal Wall Panel Machines

In today’s rapidly evolving construction and manufacturing sectors, the demand for efficient, durable, and attractive building materials is at an all-time high. Among these materials, metal wall panels have emerged as a popular choice due to their strength, longevity, and aesthetic appeal. A critical component in the production of metal wall panels is the machinery used for their fabrication. The emergence of cheap metal wall panel machines has revolutionized how businesses operate in this field, delivering cost-effective solutions without compromising on quality.

Understanding Metal Wall Panels

Metal wall panels are utilized widely in residential, commercial, and industrial applications. They serve not only as protective structures against weather elements but also contribute significantly to the overall design of buildings. Available in various colors, styles, and finishes, these panels are generally made from materials like aluminum, steel, or copper. They can be installed in different orientations, offering versatility in design while ensuring excellent insulation properties.

The Rise of Cheap Metal Wall Panel Machines

As the popularity of metal wall panels increases, so does the need for advanced machinery that can produce these panels efficiently. Historically, investing in high-quality machinery could be a significant financial burden for manufacturers. However, advancements in technology have paved the way for cheaper metal wall panel machines that are both affordable and efficient. These machines enable faster production times, reduced labor costs, and improved product consistency.

Key Features

When considering the affordability of metal wall panel machines, it’s essential to examine the key features that make them a worthy investment

1. Cost-Effectiveness One of the most significant advantages of these machines is their cost-effectiveness. Cheaper models allow businesses with tight budgets to invest in equipment that meets their production needs without breaking the bank.

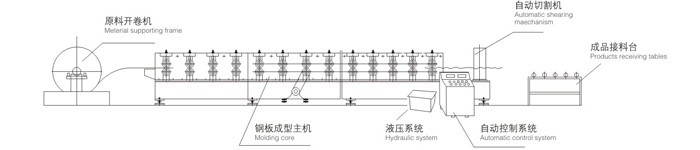

cheap metal wall panel machine

2. Efficiency Modern metal wall panel machines are designed for speed and efficiency. They can produce a higher volume of panels in a shorter amount of time, which translates to increased revenue potential for manufacturers.

3. Ease of Use Many cheaper machines come with intuitive interfaces, making them accessible even for operators with minimal training. This opens up opportunities for small businesses to hire and train staff without facing severe learning curves.

4. Durability Despite being less expensive, many of these machines are built with robust materials that ensure long-term usability under various working conditions, leading to lower maintenance costs.

5. Customizability Cheap metal wall panel machines can often be customized to produce panels of varying sizes, shapes, and thicknesses, catering to diverse market needs. This flexibility is crucial in today’s competitive market where customization is key to attracting clients.

6. Maintenance Support Manufacturers of affordable machines frequently provide excellent customer support, including comprehensive maintenance services and spare parts availability. This ensures that businesses can keep their machines running smoothly at all times.

Challenges and Considerations

While cheap metal wall panel machines offer numerous advantages, potential users must also consider several factors. It’s crucial to assess the long-term value rather than solely focusing on the initial purchase price. Companies should research brands, read reviews, and seek machinery with a good reputation for reliability and performance. Additionally, investing in training for operators can mitigate any operational mishaps and further enhance efficiency.

Conclusion

In conclusion, cheap metal wall panel machines provide an excellent opportunity for manufacturers to enter or expand within the metal panel market. By balancing affordability with functionality, these machines make it possible for businesses of all sizes to produce high-quality metal wall panels that meet the demands of modern construction. As the trend toward sustainable and aesthetically pleasing building materials continues, investing in the right machinery will undoubtedly position manufacturers for success in an increasingly competitive landscape. The future looks bright for companies willing to embrace this technology, ensuring that they remain at the forefront of innovation in construction materials.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025