Affordable Roll Forming Machines for Metal Roofing Tiles Production

Cheap Metal Roofing Tile Roll Forming Machine A Cost-Effective Solution for Your Roofing Needs

In recent years, the construction industry has witnessed a significant shift towards more affordable and durable materials for roofing. Among these materials, metal roofing has gained immense popularity due to its longevity, low maintenance, and energy efficiency. A critical component in the production of metal roofing is the metal roofing tile roll forming machine, which allows manufacturers to create high-quality roofing tiles at a fraction of the cost of traditional methods. This article explores the advantages and significance of investing in a cheap metal roofing tile roll forming machine.

The Growing Demand for Metal Roofing

Metal roofing is no longer considered just a commercial option; it has found its way into residential projects as well. Homeowners and contractors alike appreciate the benefits of metal roofs, which include

1. Durability Metal roofs can last 40 to 70 years, far exceeding the lifespan of asphalt shingles. 2. Weather Resistance Metal roofs are designed to withstand harsh weather conditions, including heavy rain, wind, and snow. 3. Energy Efficiency Many metal roofs are designed to reflect solar heat, helping to keep homes cooler during the summer months and reducing energy costs. 4. Aesthetic Appeal Available in various colors and styles, metal roofing can enhance the visual appeal of any structure.

Given these benefits, the demand for affordable metal roofing solutions continues to rise.

The Role of Roll Forming Machines

Metal roofing tile roll forming machines play a crucial role in the manufacturing process. These machines are designed to produce metal roofing tiles in continuous lengths and various profiles, ensuring that the final product meets industry standards and customer specifications. There are several reasons why investing in a roll forming machine is advantageous for manufacturers

1. Cost-Effective Production A cheap metal roofing tile roll forming machine can significantly reduce production costs. By investing in an efficient machine, manufacturers can increase their output while minimizing labor costs and material waste.

cheap metal roofing tile roll forming machine

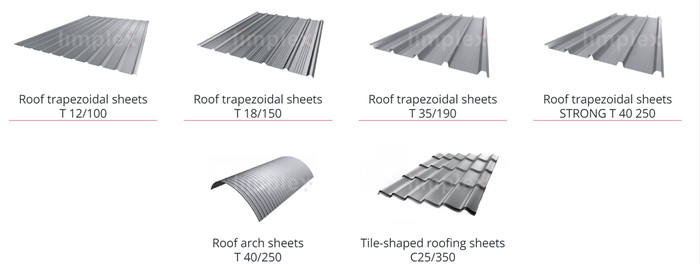

2. Versatility These machines can produce a wide range of tile styles and sizes, allowing manufacturers to cater to diverse market demands. From standing seam panels to shingles, a single roll forming machine can accommodate various roofing systems.

3. Speed and Efficiency Roll forming machines operate quickly and efficiently, reducing lead times for production. This speed allows manufacturers to fulfill large orders promptly, enhancing customer satisfaction.

4. Reduced Labor Automating the production process with a roll forming machine decreases the reliance on manual labor. This reduction not only lowers labor costs but also minimizes the potential for human error during production.

5. Quality Control Modern roll forming machines are equipped with advanced technology that ensures consistent quality in the final product. With precise control over the forming process, manufacturers can maintain high standards and deliver reliable roofing solutions.

Choosing the Right Machine

When looking for a cheap metal roofing tile roll forming machine, it is important to consider several factors

1. Specifications Ensure the machine can produce the specific types of roofing tiles you intend to manufacture. 2. Capacity Consider your production needs and choose a machine that can handle your expected output volume. 3. Supplier Reputation Research and select a reputable supplier who offers reliable machines and good customer support. 4. Warranty and Service A good warranty and after-sales service can protect your investment and ensure the machine runs smoothly for years.

Conclusion

Investing in a cheap metal roofing tile roll forming machine is a smart move for manufacturers looking to enter or expand within the metal roofing market. Not only does it enhance production efficiency and reduce costs, but it also allows businesses to meet growing consumer demand for high-quality, durable roofs. As the roofing industry continues to evolve, having the right equipment will be essential for staying competitive and meeting the needs of modern construction projects. Embrace the opportunity to innovate and capitalize on the advantages of metal roofing by incorporating roll forming technology into your manufacturing process.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025