Affordable Guardrail Roll Forming Machine Suppliers for Cost-Effective Solutions

Cheap Guardrail Roll Forming Machine Manufacturers An Overview

In the world of manufacturing, roll forming has carved out a significant niche, particularly in the production of guardrails. Cheap guardrail roll forming machines have gained popularity, especially among manufacturers looking to streamline their operations while reducing costs. This article explores the compelling features, benefits, and considerations in choosing an economical guardrail roll forming machine.

Understanding Roll Forming Machines

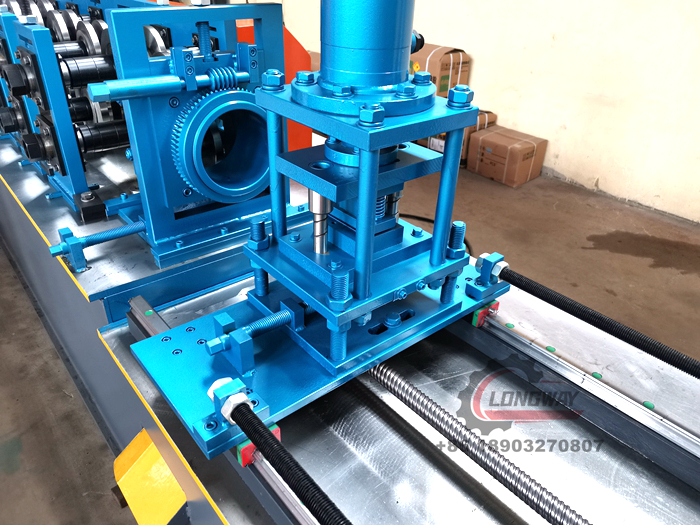

Roll forming is a continuous bending operation in which a long strip of metal is fed through consecutive pairs of rollers to form the desired cross-section shape. Guardrails, essential for road safety, are often made from various materials including steel, aluminum, and other alloys. A roll forming machine specifically designed for guardrails can produce components with high speed and precision, ensuring that each piece meets safety standards.

The Importance of Quality in Guardrail Production

When selecting a guardrail roll forming machine, it is vital to balance cost and quality. While cheaper machines are attractive, it is crucial to ensure that they do not compromise on build quality and performance. High-quality machines lead to greater durability, reduced maintenance costs, and ultimately, more reliable end products. Therefore, even when operating on a budget, manufacturers should look for machines that offer a good warranty, reliable customer support, and replacement parts availability.

Key Features of Cheap Guardrail Roll Forming Machines

1. Material Versatility Most guardrail roll forming machines can handle various materials, including cold-rolled steel and galvanized steel. This versatility allows manufacturers to meet different market demands without investing in multiple machines.

2. Speed and Efficiency Many modern machines can operate at high speeds, producing large quantities of guardrail sections in a short amount of time. This efficiency can significantly increase output and lead to higher profit margins.

3. Automation and Control Systems Advanced roll forming machines come with automation features that reduce the need for manual intervention, thus minimizing human errors. These systems can also provide real-time monitoring and diagnostics to enhance productivity.

cheap guardrail roll forming machine manufacturers

4. Compact Design Many economical roll forming machines are designed to be compact, saving valuable floor space in manufacturing facilities. This is particularly beneficial for smaller operations that may not have the capacity for larger machinery.

Benefits of Choosing Cheap Manufacturers

Opting for cheaper manufacturers offers several distinct advantages

- Cost-Effectiveness Lower investment costs ensure that even smaller enterprises can enter the market without significant financial burden. This accessibility fosters competition and encourages innovation.

- Global Sourcing With the rise of global trade, many manufacturers are sourcing roll forming machines from countries known for lower production costs. This global approach allows businesses to find value while maintaining quality standards.

- Customization Options Many cheap roll forming machine manufacturers are willing to work with clients to customize the equipment to meet specific needs. This flexibility can result in machines that are tailored precisely to a company’s production requirements.

Considerations When Choosing a Manufacturer

While the allure of low prices is strong, it is essential to conduct appropriate due diligence. Factors to consider include the manufacturer’s reputation, reviews from past customers, the availability of spare parts, and the quality of customer service. Engaging with manufacturers who have a track record of reliability and quality can save time and money in the long run.

Conclusion

In conclusion, cheap guardrail roll forming machines present an appealing option for manufacturers looking to enhance their production capabilities while maintaining budgetary constraints. However, it is crucial to carefully weigh the benefits against potential compromises in quality. By choosing the right manufacturer and machine, businesses can ensure they produce high-quality guardrails that meet stringent safety standards while enjoying cost advantages that can lead to greater competitiveness in the market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025