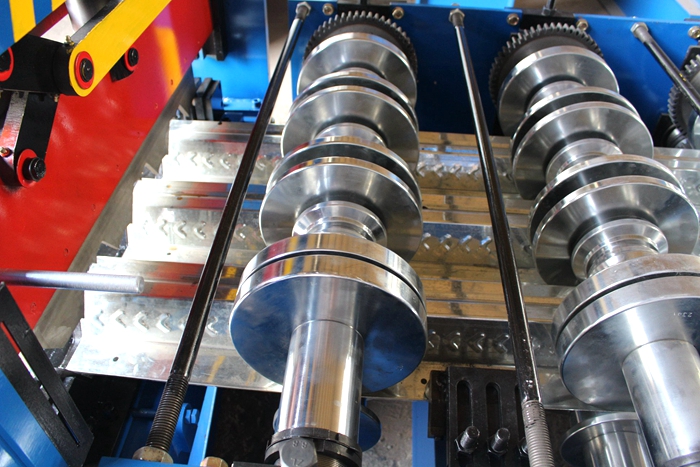

cheap floor deck forming machine

Understanding Cheap Floor Deck Forming Machines An Investment in Efficiency

In the ever-evolving construction industry, efficiency, cost-effectiveness, and quality are essential in delivering successful projects. One of the key innovations that have garnered significant attention is the floor deck forming machine. Specifically, the cheaper variants of these machines have become a focal point for contractors and builders seeking to optimize their operations without compromising quality. This article delves into the benefits, functionalities, and considerations when opting for a cheap floor deck forming machine.

What is a Floor Deck Forming Machine?

A floor deck forming machine is an advanced piece of equipment used in the construction of floors. It creates metal decking that serves as the structural foundation for concrete floors in buildings, ensuring strength and durability. These machines are designed to produce various types of floor deck profiles efficiently, allowing for rapid construction and reduced labor costs. Given the significant role floor decking plays in a building's structure, investing in the right machinery is crucial for contractors.

Advantages of Choosing a Cheap Floor Deck Forming Machine

1. Cost-Effectiveness The most apparent advantage of a cheaper floor deck forming machine is the reduced upfront investment. For small to medium-sized construction businesses, minimizing capital expenditure while maximizing productivity is often the key to survival in a competitive market. A lower-cost machine can help these companies remain cash flow positive while still delivering quality products.

2. Accessibility Many contractors and builders may have experienced barriers to entry due to the high cost of advanced machinery. With more affordable options available, smaller companies can now invest in the technology they need to compete with larger firms. This democratization of access ensures that quality construction is maintained across the industry.

3. Versatility Cheap floor deck forming machines often come equipped with various functions that cater to different project requirements. Many manufacturers offer machines that are lightweight yet robust, making them easy to transport between job sites. This versatility ensures that small to medium-sized operations can easily adapt to various projects without incurring extra costs.

cheap floor deck forming machine

Considerations When Purchasing a Cheap Floor Deck Forming Machine

While the benefits of cheap floor deck forming machines are enticing, several considerations must be taken into account before making a purchase.

1. Quality and Reliability It’s crucial to research and ensure that any cheap machinery meets industry standards and is reliable. Inferior machines may save money initially but could lead to expensive repairs or replacements in the long run. Look for machines with solid warranties and reviews from other contractors.

2. Performance Assess the performance metrics of the machine, including its speed, energy consumption, and output quality. Sometimes, cheaper machines may not perform as well as their more expensive counterparts, which can slow down production overall.

3. Maintenance and Support After purchasing a machine, ongoing maintenance and support are vital. Cheap machines may sometimes come with less robust customer service options. Ensure that the manufacturer offers adequate support and has a good reputation for assistance when things go wrong.

4. Resale Value Consider the resale value of the machine should the need arise. Sometimes, going for a lesser-known brand can result in a significant loss of value, which needs to be factored into the total cost of ownership.

Conclusion

A cheap floor deck forming machine can be an incredible asset for construction companies looking to streamline operations and reduce costs. By understanding the advantages and carefully considering the potential drawbacks, contractors can make informed decisions that position their businesses for success. Investing in the right machinery not only improves efficiency but also enhances the quality of construction projects, ultimately leading to satisfied clients and a strong reputation in the industry. As the construction landscape continues to change, leveraging technology like floor deck forming machines will be crucial for maintaining a competitive edge.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025