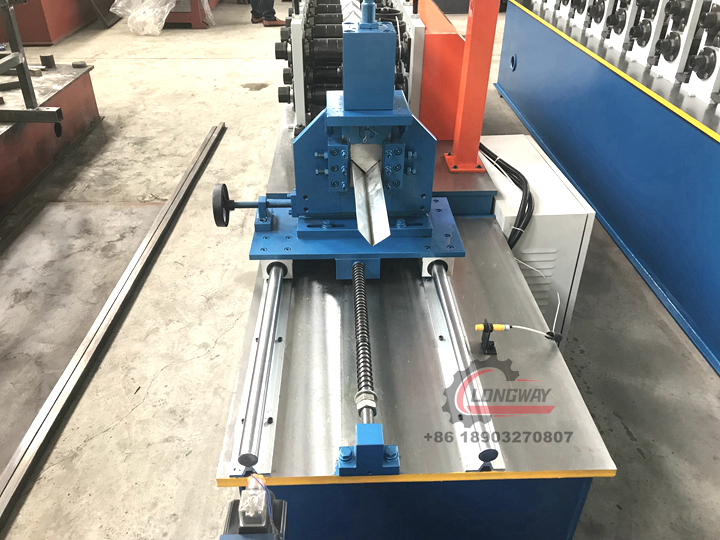

cheap downspout forming machine

Understanding Cheap Downspout Forming Machines A Cost-Effective Investment for Your Business

In today's fast-paced construction and manufacturing industries, efficiency and cost-effectiveness are key factors in maintaining a competitive edge. One of the essential tools for companies involved in the production of roofing and drainage systems is the downspout forming machine. These machines are crucial for creating downspouts, which play a vital role in directing rainwater away from buildings. While many options are available on the market, cheap downspout forming machines offer a budget-friendly solution without compromising on quality. This article explores the benefits, features, and considerations of investing in a cost-effective downspout forming machine.

Importance of Downspout Forming Machines

Downspout forming machines are specialized equipment used to manufacture downspouts from metal sheets. The process typically involves cutting, bending, and rolling the metal into the required shapes and sizes. Given the critical role downspouts play in managing water flow and protecting structures from water damage, having a reliable forming machine is paramount for businesses in this niche.

Advantages of Cheap Downspout Forming Machines

1. Cost-Effectiveness As the name suggests, cheap downspout forming machines are designed to be budget-friendly, making them accessible to small and medium-sized enterprises. This affordability allows businesses to invest in quality equipment without straining their finances.

2. High Productivity Many cost-effective downspout forming machines are designed with speed and efficiency in mind. They can produce a significant quantity of downspouts in a short amount of time, helping businesses fulfill orders promptly and improve overall productivity.

3. Ease of Use Modern downspout forming machines are typically user-friendly, allowing operators to quickly learn how to operate them. This reduces the need for extensive training and helps minimize downtime, further enhancing productivity.

4. Space Efficiency Cheap downspout forming machines often come in compact designs, making them suitable for businesses with limited workspace. Their smaller footprint allows companies to maximize their production area while still incorporating a variety of equipment.

5. Less Maintenance Affordable models are often designed with durability in mind, requiring less maintenance than their more expensive counterparts. This can lead to decreased operational costs over time as businesses spend less on repairs and replacements.

6. Customizable Options Many inexpensive downspout forming machines offer a range of customizable configurations, enabling businesses to produce different sizes and styles of downspouts without the need for multiple machines.

cheap downspout forming machine

Features to Look For

When considering a cheap downspout forming machine, it is essential to look for specific features that ensure both functionality and reliability

- Material Compatibility Ensure that the machine can handle the types of materials you plan to use, such as aluminum, galvanized steel, or copper.

- Production Capacity Assess the machine's output capacity in terms of pieces per hour. Ensure it meets your business's demand levels.

- Ease of Operation Look for machines with intuitive controls and settings that can simplify the production process.

- Durability Even though the machine is affordable, it should still be built to last. Check for quality construction, preferably using robust materials.

- After-Sales Support Reliable after-sales service and support can save you time and resources in the long run. Ensure that the supplier provides accessible customer support and potentially even warranties.

Conclusion

Investing in a cheap downspout forming machine can significantly benefit businesses involved in the production and installation of downspouts. The advantages of cost-effectiveness, high productivity, ease of use, and customizable options make these machines an appealing choice for companies looking to enhance their operations. However, it is crucial to consider specific features and seek quality suppliers that can provide adequate support.

In a competitive market, having the right tools at an affordable price is essential for growth and success. By investing in a cost-effective downspout forming machine, businesses can improve their manufacturing processes, reduce costs, and ultimately increase profitability. With careful consideration and the right choice, companies can harness the power of these machines to meet customer demands while keeping expenses in check.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025