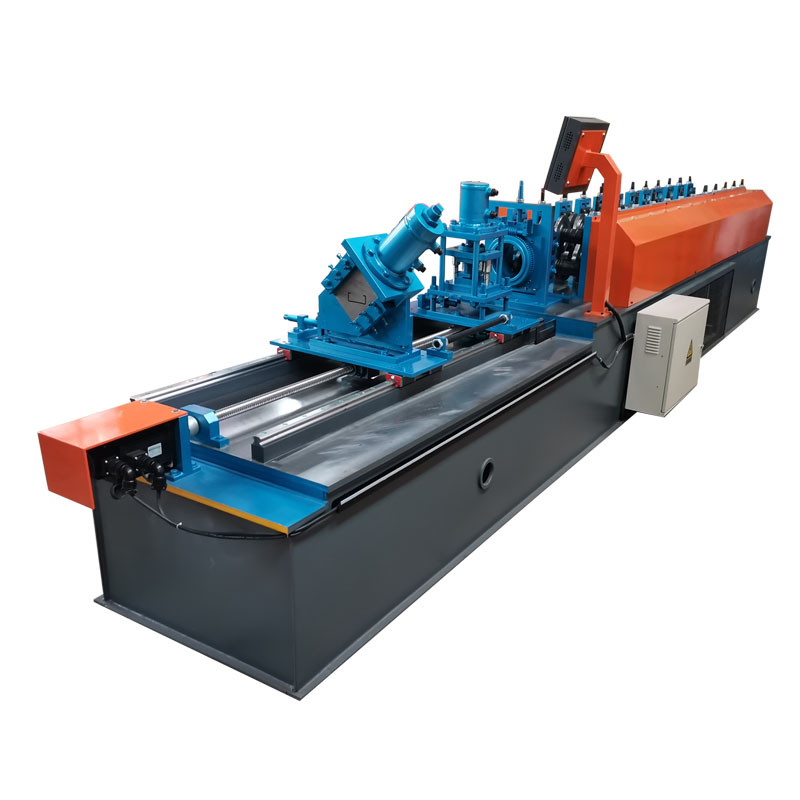

cheap cut to length and slitting line

Understanding the Cheap Cut-to-Length and Slitting Line

In the fast-paced world of manufacturing, efficiency and cost-effectiveness are paramount. One solution that has garnered attention in recent years is the cheap cut-to-length and slitting line. This processing equipment offers a streamlined approach to handling metal sheets, accommodating various industries in their quest for high-quality, customized products.

A cut-to-length line is designed to take large coils of material, typically steel or aluminum, and cut them into precise lengths as required by the customer. This process not only reduces waste by ensuring that each cut is tailored to specifications but also enhances the overall efficiency of the production process. Coupling this with a slitting line allows manufacturers to produce narrower strips of material from wider coils, providing even more versatility and options for consumers.

The cost-effectiveness of these lines is a significant selling point. Manufacturers are consistently looking for ways to minimize production costs while maintaining high standards. The implementation of a cheap cut-to-length and slitting line allows businesses to leverage bulk materials efficiently, reducing the need for excess inventory and minimizing scrap waste. Furthermore, modern technological advancements mean that even less expensive models can offer consistent, reliable performance.

cheap cut to length and slitting line

Another advantage of these lines is their adaptability. In today’s market, the ability to pivot quickly in response to changing consumer preferences is crucial. The cut-to-length and slitting lines are designed to handle various materials and thicknesses, making them an excellent investment for companies looking to diversify their offerings. This adaptability allows businesses to respond efficiently to customer demands, whether they require specific dimensions or particular materials.

Moreover, the automation involved in these lines significantly reduces labor costs. With contemporary systems, the need for manual intervention is minimized, resulting in fewer errors and quicker turnaround times. The reduced labor requirement allows companies to allocate human resources to other essential areas, boosting overall productivity.

Despite their affordability, companies should consider several factors when investing in a cut-to-length and slitting line. Quality is paramount, and it is essential to select a reputable manufacturer that uses durable materials and reliable technology. In addition, after-sales support and service are critical components to consider; a manufacturer that offers robust customer service can make a significant difference in the long-term viability and efficiency of the equipment.

In conclusion, a cheap cut-to-length and slitting line presents various benefits that make it an attractive option for manufacturers aiming to reduce costs while maximizing efficiency and flexibility. By implementing such technology, businesses can effectively navigate the complexities of modern production demands, ultimately leading to improved profit margins and greater customer satisfaction. As industries continue to evolve, those who invest wisely in efficient processing systems stand to gain a competitive edge in the marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025