cheap channel roll forming machine

Understanding Cheap Channel Roll Forming Machines

In the world of manufacturing, efficiency and cost-effectiveness are paramount. One technology that has gained significant popularity for producing various metal products is the roll forming machine, particularly the cheap channel roll forming machine. This type of machinery is designed to produce channels at a lower cost without sacrificing quality, making it an attractive option for many businesses.

What is a Roll Forming Machine?

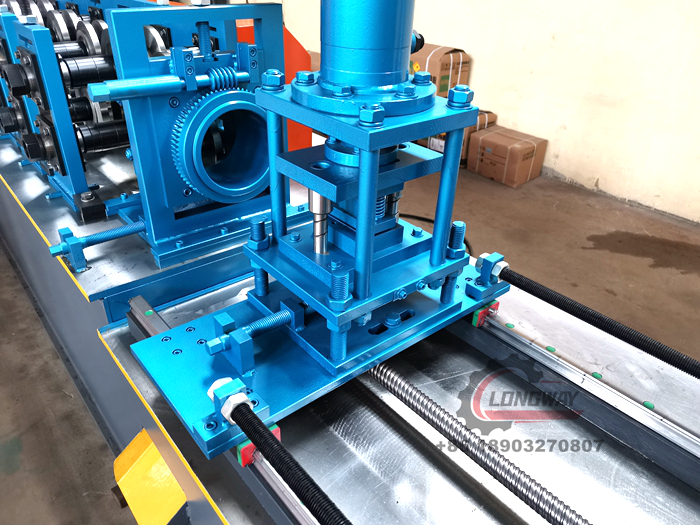

Roll forming is a continuous bending operation in which a long strip of metal stock is passed through consecutive sets of rolls to shape it into a desired cross-section. This process is particularly advantageous for creating long pieces of uniform shape and size. A roll forming machine consists of several key components, including the decoiler, forming roller stations, cutting system, and a control system.

The Benefits of Cheap Channel Roll Forming Machines

1. Cost-Effectiveness As the name suggests, cheap channel roll forming machines are designed to be budget-friendly. They typically use less expensive materials and simpler manufacturing processes, which reduces the overall cost of the machine itself. This is particularly appealing to small and medium-sized enterprises looking to optimize their production without significant financial investment.

2. High Efficiency These machines are capable of producing channels quickly and continuously, which enhances the overall production efficiency. In high-demand environments, where time is money, a cheap channel roll forming machine can meet production targets without the need for extensive labor or multiple setups.

3. Versatility Despite being labeled cheap, these machines are quite versatile. They can be customized to produce various channel sizes and shapes based on specific project requirements. This adaptability allows manufacturers to cater to different markets, from construction and automotive to furniture and appliances.

4. Quality Production Many manufacturers assume that lower costs mean lower quality. However, many modern cheap channel roll forming machines use advanced technologies and materials that can produce high-quality, precise parts. This ensures minimal waste and optimized production processes.

cheap channel roll forming machine

5. Reduced Labor Costs With the automation capabilities of modern roll forming machines, the need for extensive manual labor is significantly reduced. Operators can oversee multiple machines, maximizing productivity and reducing labor costs.

The Technology Behind Cheap Channel Roll Forming Machines

Modern cheap channel roll forming machines utilize computer numerical control (CNC) technology, which enhances precision and consistency in production. CNC systems allow for easy adjustments to the machine to accommodate different designs and specifications quickly.

Moreover, these machines often incorporate programmable logic controllers (PLCs) that monitor the entire system's performance, ensuring smooth operation and immediate detection of any issues. These technological advancements enhance the reliability of the machines, further justifying their presence in a manufacturing setup.

Applications of Channel Roll Forming Machines

Cheap channel roll forming machines are utilized across various industries. Some common applications include

- Construction Channels are employed in framing and structural applications due to their strength and durability. - Automotive The automotive industry utilizes channels for both structural components and aesthetic features. - Furniture Channels are also used in the production of furniture frames, providing stability and design versatility. - HVAC Many heating, ventilation, and air conditioning systems incorporate channel components for ductwork.

Conclusion

In conclusion, cheap channel roll forming machines provide an economical and efficient solution for producing channel sections of metal. Their versatility, combined with the advanced technology integrated into modern designs, offers manufacturers the opportunity to produce high-quality products at a lower cost. As industries continue to seek ways to reduce production expenses while maintaining quality, the demand for cheap yet effective roll forming machines is likely to grow. This machinery not only plays a crucial role in improving manufacturing processes but also helps businesses remain competitive in an ever-evolving market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025