Efficient Solutions for Channel Roll Forming Machine Quotes and Pricing Options

Understanding Channel Roll Forming Machines Quotes and Insights

In the realm of manufacturing, the demand for precision and efficiency is paramount. One essential machine that meets these criteria is the channel roll forming machine. This innovative equipment plays a crucial role in producing channel sections that are widely used in construction, automotive, and other industries. In this article, we will explore the significance of channel roll forming machines, the factors influencing their pricing, and what to consider when obtaining quotes.

What is a Channel Roll Forming Machine?

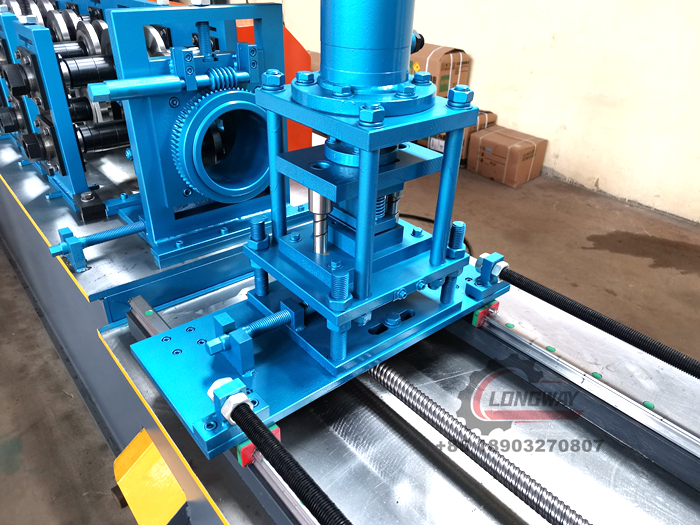

A channel roll forming machine is designed specifically to create channel-shaped profiles from metal. The process involves feeding a continuous strip of metal through a series of rollers that gradually shape it into a channel form. This method is not only efficient but also allows for high precision in the dimensions of the channel produced. Common materials processed by these machines include steel, aluminum, and stainless steel, all of which have distinct applications based on their durability and weight.

Importance of Channel Roll Forming Machines

Channel roll forming machines offer several advantages that contribute to their widespread use

1. High Productivity These machines can produce large volumes of channel sections in a relatively short period, making them ideal for industries with high demands.

2. Consistency and Quality The automated nature of roll forming ensures that the finished products meet stringent quality standards. Every channel produced is uniform in shape and size, reducing waste and increasing efficiency.

3. Versatility With adjustable roller configurations, channel roll forming machines can produce various sizes and shapes of channels, allowing manufacturers to cater to diverse customer specifications.

Factors Influencing the Cost of Channel Roll Forming Machines

When considering a purchase, companies often seek quotes from manufacturers. Understanding the factors that influence the pricing of these machines is essential for making an informed decision

1. Machine Specifications The complexity of the machine, including the number of rollers, the materials used in construction, and the machine's overall capabilities, will directly impact the price. More advanced machines with added features and customization options typically cost more.

channel roll forming machine quotes

2. Production Capacity Machines designed for higher output levels tend to be more expensive. Manufacturers should assess their production needs to find a machine that strikes the right balance between capacity and cost.

3. Technology and Automation Machines that incorporate advanced technology, such as automation for material handling or CNC controls for precision, are usually priced higher due to the initial investment but may lead to long-term savings.

4. Brand Reputation Established manufacturers often have a proven track record of producing reliable and durable machines. While their products may come at a higher price point, the investment can pay off with lower maintenance costs and better support.

5. Service and Support Quotes may also vary based on the level of service and support included, such as warranty periods, training, and after-sales support. These factors should not be overlooked when evaluating the total cost of ownership.

Requesting Quotes Best Practices

When seeking quotes for channel roll forming machines, consider the following tips

1. Specify Requirements Clearly define your production needs, including the materials to be used and the expected output. This information helps manufacturers provide more accurate quotes.

2. Compare Multiple Quotes Obtaining quotes from several manufacturers allows you to gain insights into market prices and options available.

3. Investigate the Manufacturer’s Reputation Look for reviews and testimonials to gauge the reliability and performance of the machines from various suppliers.

4. Request Detailed Proposals Ensure that quotes include breakdowns of costs, including any potential additional charges for shipping, installation, and training.

Conclusion

Investing in a channel roll forming machine is a significant decision that can impact a company’s production capabilities and overall efficiency. By understanding the factors influencing the cost and taking a strategic approach to obtaining quotes, manufacturers can make informed choices that align with their operational goals. As industries continue to evolve, the role of channel roll forming machines will remain vital, driving innovation and contributing to enhanced manufacturing processes across various sectors.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025