Jan . 28, 2025 02:48

Back to list

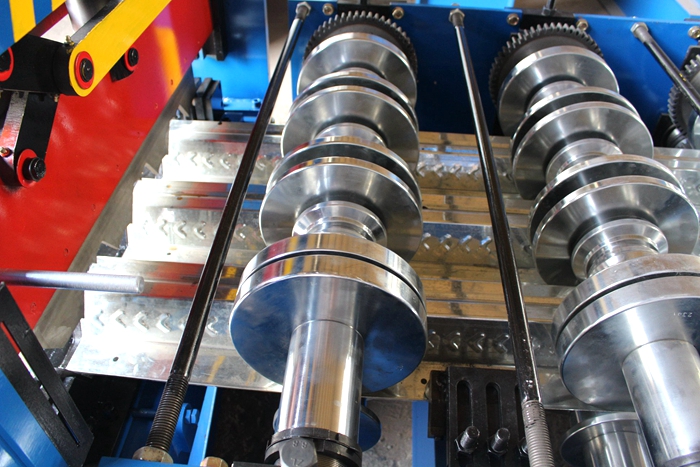

cladding roll forming machine

Channel roll forming machines have become an indispensable tool in the manufacturing industry, particularly in the production of channel sections used across various sectors such as construction, automotive, and infrastructure. These machines employ advanced technology to transform flat metal sheets into specific channel shapes, providing unmatched precision and efficiency. Leveraging personal experience and industry insight, this article explores the technological advancements, applications, and benefits of channel roll forming machines, establishing their essential role in modern manufacturing processes.

Credibility in the use and implementation of channel roll forming machines is enhanced by ongoing research and collaboration with industry experts to refine machine functionalities. Many manufacturers continue to test and develop innovative features, such as advanced control systems and real-time monitoring capabilities, which enhance operational convenience and product quality. These developments not only improve machine performance but also reinforce trust among end-users who rely on their reliability for high-stakes projects. Investing in a channel roll forming machine is a strategic decision informed by tangible benefits in production efficiency and product quality. The ability to produce precise, consistent channel profiles translates to enhanced customer satisfaction and competitive advantage in the marketplace. Furthermore, the reduced material wastage and energy consumption contribute to more sustainable production practices, aligning with global movements towards environmental responsibility. Despite the evident benefits, selecting the right channel roll forming machine requires careful consideration of factors such as specific production needs, material types, and desired channel configurations. Engaging with experts and conducting thorough market research can prove invaluable in making informed decisions. Manufacturers offer various models, each with specific capabilities and features tailored to meet distinct production demands. In conclusion, channel roll forming machines are more than just another piece of equipment; they are a pivotal component of modern manufacturing landscapes. Their advanced features, combined with versatile application potential and cost-effectiveness, make them indispensable for businesses aiming to enhance their manufacturing processes. By embracing these machines, companies can achieve superior product quality, operational efficiency, and sustainability, all critical metrics in today’s competitive industrial environment.

Credibility in the use and implementation of channel roll forming machines is enhanced by ongoing research and collaboration with industry experts to refine machine functionalities. Many manufacturers continue to test and develop innovative features, such as advanced control systems and real-time monitoring capabilities, which enhance operational convenience and product quality. These developments not only improve machine performance but also reinforce trust among end-users who rely on their reliability for high-stakes projects. Investing in a channel roll forming machine is a strategic decision informed by tangible benefits in production efficiency and product quality. The ability to produce precise, consistent channel profiles translates to enhanced customer satisfaction and competitive advantage in the marketplace. Furthermore, the reduced material wastage and energy consumption contribute to more sustainable production practices, aligning with global movements towards environmental responsibility. Despite the evident benefits, selecting the right channel roll forming machine requires careful consideration of factors such as specific production needs, material types, and desired channel configurations. Engaging with experts and conducting thorough market research can prove invaluable in making informed decisions. Manufacturers offer various models, each with specific capabilities and features tailored to meet distinct production demands. In conclusion, channel roll forming machines are more than just another piece of equipment; they are a pivotal component of modern manufacturing landscapes. Their advanced features, combined with versatile application potential and cost-effectiveness, make them indispensable for businesses aiming to enhance their manufacturing processes. By embracing these machines, companies can achieve superior product quality, operational efficiency, and sustainability, all critical metrics in today’s competitive industrial environment.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products