Leading Manufacturers of Channel Forming Machines for Efficient Production Solutions

The Evolution and Impact of Channel Forming Machine Manufacturers

The industrial landscape is continuously evolving, shaped by technological advancements and increasing demand for products that meet specific criteria. One significant area that has witnessed this transformation is the production of channel forming machines. These machines are essential in the manufacturing of channels that are used in various applications, including construction, electrical components, and automotive parts. Understanding the role of channel forming machine manufacturers provides insight into both the industrial process and the technological innovation driving the sector.

Understanding Channel Forming Machines

Channel forming machines are specialized equipment designed to shape raw materials, typically metal, into channels that serve a myriad of purposes. The process involves feeding metal sheets into the machine, which then molds them into specific channel configurations through a series of bending, cutting, and shaping techniques. The finished products are crucial for creating structural frameworks in buildings, designing duct systems, and crafting component casings.

The machinery can produce various channel sizes and shapes, catering to diverse industry requirements. With advancements in manufacturing technology, modern channel forming machines are often equipped with computer numerical control (CNC) capabilities, allowing for precise and efficient production. This technological integration enhances productivity, reduces waste, and ensures consistent quality across high-volume production runs.

The Role of Manufacturers

Channel forming machine manufacturers play a critical role in this production ecosystem. They are responsible for the design, development, and distribution of these vital machines. A key factor that distinguishes leading manufacturers is their commitment to innovation. By adopting cutting-edge technology, such as automation and robotics, manufacturers can improve the efficiency and capabilities of their machines.

Moreover, many manufacturers are investing in research and development (R&D) to explore new materials and technologies that can lead to more sustainable practices. In an era where environmental awareness is at the forefront, manufacturers are under pressure to minimize their carbon footprint while producing high-quality machinery.

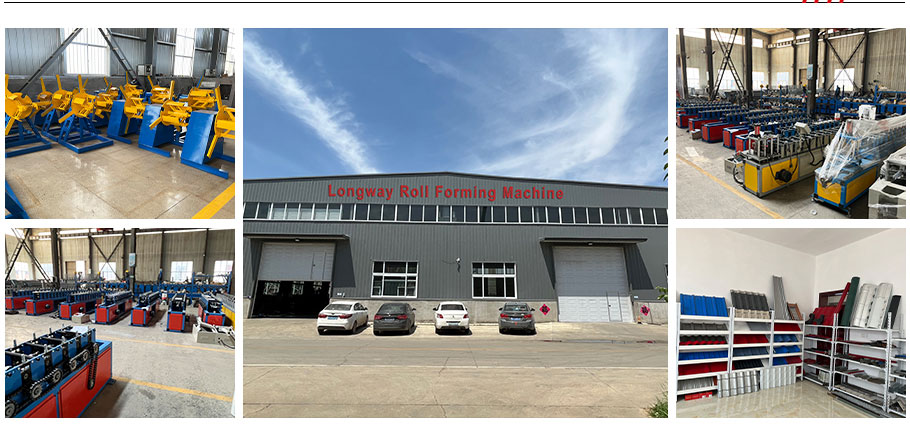

channel forming machine manufacturers

Market Dynamics

The global market for channel forming machines is influenced by several factors. The growth of the construction and automotive industries, for instance, directly impacts the demand for channel forming machines. As infrastructure projects expand and the automotive industry shifts towards electric vehicles, the need for innovative manufacturing solutions intensifies. Furthermore, the advent of Industry 4.0—characterized by smart manufacturing and the Internet of Things (IoT)—is reshaping how manufacturers operate and compete in the global market.

Emerging markets, particularly in Asia-Pacific and Latin America, show significant potential for growth. As these regions industrialize, the demand for efficient and reliable channel forming solutions is set to rise. Local manufacturers are also capitalizing on this opportunity to cater to regional needs while competing globally.

Challenges and Opportunities

Despite the promising landscape, channel forming machine manufacturers face several challenges. Supply chain disruptions, particularly following the COVID-19 pandemic, have highlighted the vulnerabilities in sourcing raw materials. Manufacturers must now navigate these challenges while also tackling rising labor costs and the need for constant technological upgrades.

On the flip side, these challenges present unique opportunities for manufacturers that can adapt swiftly. Emphasizing customization, enhancing customer service, and embracing digital transformation are strategies that can set manufacturers apart in a competitive market. By leveraging data analytics and customer feedback, they can optimize product design and improve operational efficiency.

Conclusion

Channel forming machine manufacturers are pivotal players in various industrial sectors, driving innovation and facilitating the production of essential components. As the market evolves, with increasing demands for efficiency and sustainability, these manufacturers must remain agile, embracing technological advancements while addressing emerging challenges. By doing so, they will not only contribute to the industry’s growth but also play a crucial role in the broader economic landscape. The future looks bright for those willing to innovate and adapt in this fast-changing manufacturing environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025