Innovative Solutions for Channel Production Using Advanced Forming Technologies

The Channel Forming Machine A Key Innovation in Manufacturing

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. One of the standout innovations that have contributed significantly to achieving these goals is the channel forming machine. This specialized equipment is designed to create channels and profiles that are integral to various structural applications, ranging from industrial buildings to residential constructions. In this article, we will explore the functionalities, advantages, and applications of channel forming machines, as well as their impact on modern manufacturing processes.

What is a Channel Forming Machine?

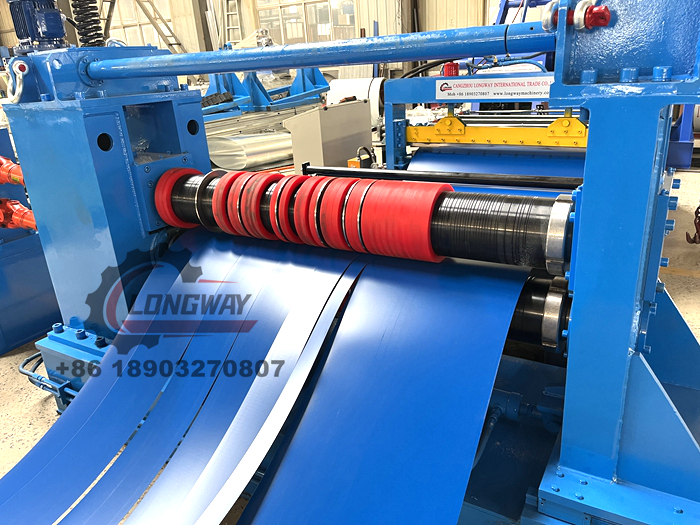

A channel forming machine is a type of roll forming equipment that is utilized to create metal channels from flat sheets or coils. It employs a series of rollers that progressively shape the material into the desired channel profile. The process typically involves feeding the flat material through the machine, where it is bent and shaped into channels that can vary in size, width, and thickness according to specific requirements.

Key Features of Channel Forming Machines

1. Roll Forming Process Channel forming machines utilize a continuous roll forming process, which allows for high production speeds and reduced material waste. As the material passes through the rollers, it is gradually shaped without the need for cutting, which ensures a uniform final product.

2. Customization One of the major advantages of channel forming machines is their ability to produce customized profiles. Manufacturers can adjust the rollers and settings to create a wide range of channel sizes and configurations, catering to different project specifications.

3. Durability and Strength The machines are designed to work with various materials, predominantly steel and aluminum. The resulting channels exhibit excellent strength and durability, making them suitable for structural applications that require robust support.

4. Automation and Integration Many modern channel forming machines are equipped with advanced automation features that enhance productivity. These machines can be integrated with other manufacturing processes, including cutting, welding, and assembly, creating a seamless production line.

Advantages of Using Channel Forming Machines

channel forming machine

1. Efficiency and Speed The automated nature of channel forming machines allows for rapid production cycles. This increased speed not only reduces lead times but also enables manufacturers to meet high demand without compromising on quality.

2. Cost-Effectiveness By minimizing material waste and reducing labor costs through automation, channel forming machines offer a cost-effective solution for producing metal channels. Businesses can achieve higher profit margins while maintaining competitive pricing.

3. Consistent Quality The precision of the roll forming process ensures that each channel produced meets stringent quality standards. This consistency is crucial for structural applications where safety and reliability are paramount.

4. Versatile Applications Channel forming machines are not limited to one industry; they find applications across various sectors, including construction, automotive, aerospace, and manufacturing. They are used to produce components such as support beams, brackets, and frames, making them a versatile tool in any manufacturing setup.

Applications in Modern Manufacturing

In the construction industry, channel forming machines play a vital role in creating structural components that provide essential support to buildings and infrastructure. For example, metal channels are commonly used in the framing of walls and roofs, contributing to the overall stability and durability of structures.

In the automotive sector, channel formed parts are often used in chassis and body structures, where strength and weight reduction are critical factors. The aerospace industry also benefits from this technology, producing lightweight yet strong components for aircraft that meet stringent regulatory requirements.

Conclusion

The channel forming machine represents a significant advancement in manufacturing technology. Its ability to produce high-quality metal channels with efficiency and precision has transformed how manufacturers approach the production of structural components. As industries strive for greater efficiency and sustainability, the role of channel forming machines will continue to expand, driving innovation and enhancing productivity across various sectors. Embracing this technology is not just about keeping pace with competition; it is also about laying the foundation for a more robust and versatile manufacturing future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025