Feb . 07, 2025 02:12

Back to list

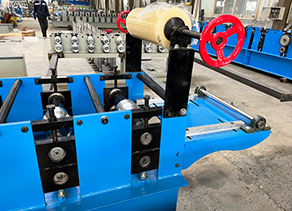

ceiling t grid roll forming machine

In the rapidly evolving world of manufacturing, the ceiling T grid roll forming machine stands out as a transformative piece of equipment. This machine plays a crucial role in the production of ceiling T grids, fundamental components that support ceiling tiles in suspended ceiling systems. Commonly seen in commercial and residential buildings, these grids offer an aesthetic finish while concealing structural steel and wiring. Heres a comprehensive exploration into the essence, function, and expertise surrounding the ceiling T grid roll forming machine.

Resource sustainability has become a critical consideration in today's environmentally-conscious industry. Modern ceiling T grid roll forming machines are designed to minimize waste and reduce energy consumption, aligning with green manufacturing practices. By optimizing the use of raw material and reducing machine downtime, manufacturers demonstrate their commitment to eco-friendly practices, further strengthening consumer trust and enhancing brand loyalty. For businesses looking to invest in a ceiling T grid roll forming machine, partnering with a knowledgeable supplier is crucial. These experts can provide detailed guidance tailored to a company's specific production needs, ensuring buyers make informed decisions. From initial purchase considerations to ongoing maintenance support, expert suppliers offer invaluable insights and services that can help streamline operations and facilitate long-term success. The upwards trajectory of the ceiling T grid market indicates a robust demand for high-performing, versatile machinery. As building trends evolve towards modular and aesthetic constructions, the need for adaptable, efficient ceiling solutions grows. Consequently, the role of the ceiling T grid roll forming machine becomes even more significant, driving innovation in the architectural landscape. In conclusion, the ceiling T grid roll forming machine transcends its role as mere machinery—acting as a cornerstone in modern construction projects, embodying technological prowess, unwavering reliability, and sustainable practices. Its contribution to enhancing construction aesthetics and functionality underscores its importance in the architectural and design industries, shaping spaces that marry form and function with minimal footprint. This narrative of quality, expertise, and trustworthiness solidifies its place as an essential tool in the world of construction and manufacturing.

Resource sustainability has become a critical consideration in today's environmentally-conscious industry. Modern ceiling T grid roll forming machines are designed to minimize waste and reduce energy consumption, aligning with green manufacturing practices. By optimizing the use of raw material and reducing machine downtime, manufacturers demonstrate their commitment to eco-friendly practices, further strengthening consumer trust and enhancing brand loyalty. For businesses looking to invest in a ceiling T grid roll forming machine, partnering with a knowledgeable supplier is crucial. These experts can provide detailed guidance tailored to a company's specific production needs, ensuring buyers make informed decisions. From initial purchase considerations to ongoing maintenance support, expert suppliers offer invaluable insights and services that can help streamline operations and facilitate long-term success. The upwards trajectory of the ceiling T grid market indicates a robust demand for high-performing, versatile machinery. As building trends evolve towards modular and aesthetic constructions, the need for adaptable, efficient ceiling solutions grows. Consequently, the role of the ceiling T grid roll forming machine becomes even more significant, driving innovation in the architectural landscape. In conclusion, the ceiling T grid roll forming machine transcends its role as mere machinery—acting as a cornerstone in modern construction projects, embodying technological prowess, unwavering reliability, and sustainable practices. Its contribution to enhancing construction aesthetics and functionality underscores its importance in the architectural and design industries, shaping spaces that marry form and function with minimal footprint. This narrative of quality, expertise, and trustworthiness solidifies its place as an essential tool in the world of construction and manufacturing.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products