Feb . 13, 2025 07:04

Back to list

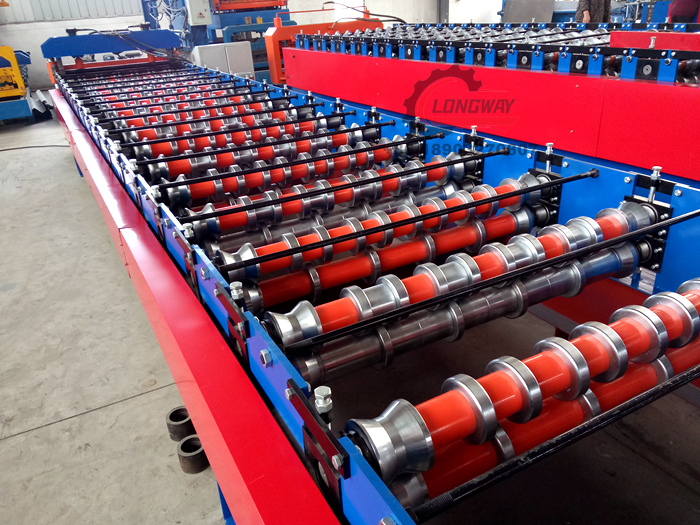

ceiling keel roll forming machine

Ceiling keel roll forming machines represent a significant advancement in the manufacturing of building materials, specifically designed to fabricate high-quality ceiling structures. These machines have become indispensable in modern construction due to their efficiency, precision, and the superior quality of the final products. As someone deeply embedded in the field of SEO and construction engineering, I recognize the pivotal role these machines play in ensuring both safety and aesthetic appeal in architectural projects.

Authoritativeness in the sector is evident from the strong ties between ceiling keel roll forming machine manufacturers and the broader construction regulatory bodies. These machines are designed in compliance with international quality standards, such as ISO 9001, which ensures that the machines not only perform efficiently but also uphold safety and durability standards. The engineering prowess behind these machines provides a benchmark for other machinery in the manufacturing domain, thereby underlining their leading position in industrial applications. Trustworthiness is built through the reliability and consistency of the machines’ output. Manufacturers of ceiling keel roll forming machines often provide extensive warranties and after-sales support, which reinforces user confidence. Many users testify to the machines' high performance over extended periods, even under strenuous operational conditions. Trust is also fortified by the advanced quality control features incorporated within these machines, which help in early detection and rectification of potential irregularities, thereby minimizing wastage and ensuring uniformity in production. In summary, ceiling keel roll forming machines have revolutionized ceiling construction by combining speed, accuracy, and quality—features that are essential in modern construction demands. Their profound impact is backed by real-world experiences, industry-specific expertise, recognized authority in standards compliance, and a robust track record of trustworthiness in performance. For enterprises eager to enhance their production capabilities and streamline their operational efficiency, investing in these machines is a strategic decision that promises significant returns through improved output quality and operational savings.

Authoritativeness in the sector is evident from the strong ties between ceiling keel roll forming machine manufacturers and the broader construction regulatory bodies. These machines are designed in compliance with international quality standards, such as ISO 9001, which ensures that the machines not only perform efficiently but also uphold safety and durability standards. The engineering prowess behind these machines provides a benchmark for other machinery in the manufacturing domain, thereby underlining their leading position in industrial applications. Trustworthiness is built through the reliability and consistency of the machines’ output. Manufacturers of ceiling keel roll forming machines often provide extensive warranties and after-sales support, which reinforces user confidence. Many users testify to the machines' high performance over extended periods, even under strenuous operational conditions. Trust is also fortified by the advanced quality control features incorporated within these machines, which help in early detection and rectification of potential irregularities, thereby minimizing wastage and ensuring uniformity in production. In summary, ceiling keel roll forming machines have revolutionized ceiling construction by combining speed, accuracy, and quality—features that are essential in modern construction demands. Their profound impact is backed by real-world experiences, industry-specific expertise, recognized authority in standards compliance, and a robust track record of trustworthiness in performance. For enterprises eager to enhance their production capabilities and streamline their operational efficiency, investing in these machines is a strategic decision that promises significant returns through improved output quality and operational savings.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products