Top Manufacturer of CD UD CW UD Roll Forming Equipment and Solutions

The Evolution of CD, UD, CW, and UD Roll Formers A Comprehensive Overview

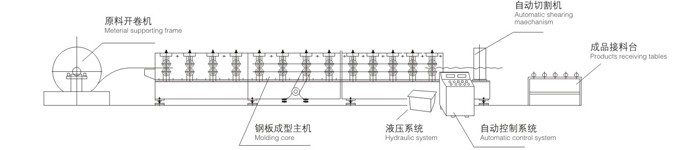

In the realm of metal forming technology, the CD (C-Section), UD (U-Section), and CW (C-Section Wall) roll formers have established themselves as essential tools for manufacturers. These machines are integral in producing high-precision metal profiles that are critical for various construction applications such as framing, roofing, and support systems. As global demand for efficient metal fabrication increases, the importance of capable roll former manufacturers becomes ever more pronounced.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of sheet metal is gradually shaped into the desired cross-section by passing it through a series of rotating rolls. This method is particularly suited for producing shapes with uniform cross-sections, making it ideal for the production of CD, UD, and CW profiles. These profiles are primarily used in the construction industry and are favored for their strength, lightweight properties, and ease of installation.

CD and UD profiles are typically made from thin sheets of metal, usually galvanized steel, and are used as structural components in the construction of walls and ceilings. The CW profiles serve as wall studs, providing critical support within wall assemblies. The versatility and effectiveness of these profiles have made them a staple in modern construction practices.

The Role of Manufacturers

The efficiency, precision, and reliability of roll forming operations depend significantly on the manufacturing capabilities of roll former producers. High-quality CD, UD, and CW roll formers use advanced technology to ensure that the final product meets stringent industry specifications. Manufacturers are increasingly investing in cutting-edge machinery and automation systems to enhance production rates and minimize waste, thereby offering a competitive edge in the market.

Leading roll former manufacturers emphasize the importance of customization. Each construction project may have unique specifications, and the ability to produce tailored profiles allows manufacturers to meet diverse needs effectively. Offering custom solutions not only improves client satisfaction but also fosters long-term partnerships with contractors and builders.

cd ud cw ud roll former manufacturer

Advancements in Technology

The ongoing advancement of technology in roll former manufacturing is reshaping the industry. Modern CNC (Computer Numerical Control) systems and integrated software solutions enable manufacturers to design and produce complex profiles with unprecedented accuracy. Moreover, advancements in materials science have resulted in the development of stronger and more lightweight materials, further enhancing the capabilities of CD, UD, and CW roll forming machines.

Automation is also playing a pivotal role in streamlining production processes. Automated stacking, packaging, and quality control systems can significantly reduce labor costs and improve overall efficiency. By integrating the latest technologies, manufacturers can produce higher volumes of profiles while maintaining consistent quality.

Environmental Considerations

In addition to technological advancements, there is a growing emphasis on sustainability within the industry. Manufacturers are becoming more conscious of their environmental impact, adopting practices such as recycling scrap metal and reducing energy consumption during production. By focusing on sustainable practices, roll former manufacturers not only contribute to environmental protection but can also appeal to a market that increasingly values eco-friendly solutions.

Conclusion

As the demand for high-quality metal profiles continues to rise, the role of CD, UD, and CW roll former manufacturers has never been more critical. Their ability to blend advanced technology, customization, and sustainable practices positions them at the forefront of the construction industry. As we move forward, the relationship between manufacturers and their clients will continue to evolve, driving innovation and efficiency in the production of essential metal profiles. The future of roll forming looks promising, and it will be exciting to see how manufacturers adapt to meet the challenges and opportunities ahead.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025