C Channel Rolling Machine Producer for High-Quality Metal Fabrication Solutions

The Importance of a Reliable C-Channel Rolling Machine Manufacturer

In the modern manufacturing industry, efficiency and precision are paramount, particularly when it comes to metal fabrication. Among the various machines that play a crucial role in this sector is the C-channel rolling machine. This specialized equipment is essential for producing C-shaped channels used in construction, automotive, and various structural applications. Choosing the right manufacturer for your C-channel rolling machine can significantly impact your production quality and operational efficiency.

Understanding C-Channel Rolling Machines

A C-channel rolling machine is designed to create C-shaped steel channels by processing flat metal sheets into the desired profile. The machine works by feeding the flat metal into a series of rollers that shape the metal through a combination of bending and forming processes. The precision with which these machines operate determines the quality and consistency of the final product. As such, investing in a high-quality rolling machine is crucial for any business that relies on mass production of these components.

The Role of a Manufacturer

Selecting a reputable C-channel rolling machine manufacturer is fundamental to ensuring that you acquire a reliable and efficient piece of equipment. A good manufacturer not only provides machines but also offers comprehensive support services, including installation, maintenance, and training. Therefore, it is essential to assess the manufacturer’s track record, customer reviews, and industry reputation before making a purchase.

Key Factors to Consider

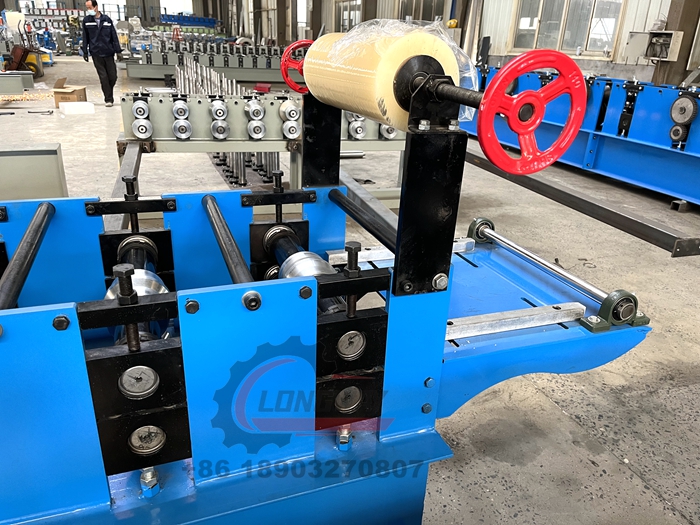

c channel rolling machine manufacturer

1. Quality of Machinery The foremost consideration should be the quality and durability of the machines being offered. Manufacturers that utilize high-grade materials and cutting-edge technology will produce machines that can withstand rigorous use and deliver superior performance over time.

2. Customization Options Different industries may require different specifications regarding the dimensions and profiles of the C-channels. Choosing a manufacturer that offers customization options can help fulfill specific production requirements, ensuring that machinery is equipped to handle various designs and dimensions.

3. After-Sales Support Reliable after-sales support is crucial for minimizing downtime in your operations. A manufacturer that provides ongoing technical support, easy access to spare parts, and maintenance services can significantly reduce the potential operational disruptions caused by machine malfunctions.

4. Technological Advancements The evolution of rolling machine technology can greatly enhance productivity. Manufacturers that integrate computer numerical control (CNC) technology or automation into their machines can offer improved accuracy, efficiency, and reduced labor costs.

5. Training and Resources A reputable manufacturer will often provide training for your staff to ensure they can operate the machinery effectively. This training not only helps in maximizing the machine’s potential but also ensures worker safety and adherence to best practices.

Conclusion

The selection of a C-channel rolling machine manufacturer is a decision that warrants careful consideration. The right manufacturer can provide you with a machine that enhances your production capability and ensures quality output. It is essential to do thorough research, assess your own production needs, and consider all factors discussed to make an informed decision. By choosing the right partner in the manufacturing process, you can ensure that your operations are efficient, cost-effective, and capable of meeting the demands of your clients. Ultimately, investing in a quality C-channel rolling machine and a trustworthy manufacturer is not merely a purchase; it is a strategic move towards the long-term success of your manufacturing endeavors.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025