c channel rolling machine factory

Understanding C Channel Rolling Machines A Key Element in Metal Fabrication

C channel rolling machines have emerged as vital tools in the metal fabrication industry, specifically for shaping C-shaped steel channels. These machines are designed to create channels that are pivotal for a range of structural applications, from construction to manufacturing. In this article, we will delve into the functions, benefits, and significance of C channel rolling machines, shedding light on their essential role in modern industry.

The Basics of C Channel Rolling Machines

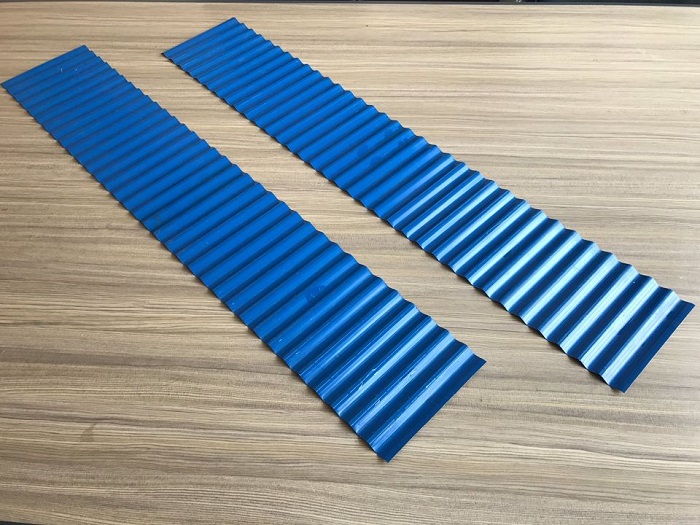

C channel rolling machines utilize a process known as roll forming to create C-shaped profiles from flat steel sheets. The machine functions by passing the flat metal through a series of rollers that gradually shape it into the desired C channel form. Traditional methods of metal bending can be time-consuming and less precise; however, rolling machines offer enhanced efficiency and accuracy.

Typically, these machines consist of several critical components, including rollers, feeding mechanisms, and control systems. The rollers come in different configurations, allowing for the production of various channel sizes and thicknesses. The feeding mechanism ensures smooth and consistent feeding of the metal sheet, while the control system allows the operator to precisely manage the speed and shape of the output.

Advantages of Using C Channel Rolling Machines

1. Efficiency and Speed One of the primary advantages of C channel rolling machines is their ability to produce high volumes of C channels in a relatively short time. This attribute makes them invaluable for industries that require large quantities of metal components, ensuring that production schedules are met without compromising quality.

2. Precision and Quality Modern C channel rolling machines are equipped with advanced technology that allows for high precision in the shaping process. This precision minimizes waste and ensures that the final products meet exact specifications, which is crucial in construction and engineering applications.

3. Versatility These machines are not limited to creating C-shaped channels; with the right adjustments, they can also produce other profiles, including U channels and other complex shapes. This versatility allows manufacturers to utilize a single machine for multiple applications, thereby reducing investment costs.

c channel rolling machine factory

4. Cost-Effectiveness By automating the process of forming C channels, companies can significantly reduce labor costs. Additionally, the reduced material waste and higher efficiency contribute to overall cost savings, making C channel rolling machines an attractive option for manufacturers.

Applications of C Channels

C channels are widely used in various applications, chiefly in the construction sector. They are commonly used as structural supports in buildings, bridges, and other infrastructure projects due to their excellent strength-to-weight ratio. Additionally, C channels serve as components in manufacturing equipment, truck and ship frames, and as platforms in heavy machinery.

In manufacturing, C channels contribute to the assembly of racks, shelves, and other storage solutions. Their adaptability allows them to be utilized in residential, commercial, and industrial projects, enhancing the functionality and stability of constructions.

The Future of C Channel Rolling Machines

As the manufacturing industry continues to evolve, the demand for advanced C channel rolling machines is expected to grow. Technological advancements, such as the integration of automation and artificial intelligence, promise to further enhance the efficiency and precision of these machines. Manufacturers are likely to adopt smart rolling machines that can monitor performance in real time, optimize production processes, and reduce energy consumption.

Moreover, the ongoing push for sustainability and eco-friendliness in manufacturing practices necessitates innovations in metal processing that minimize waste and utilize renewable energy sources. C channel rolling machines will undoubtedly play a pivotal role in the transition towards greener manufacturing processes.

Conclusion

In conclusion, C channel rolling machines are indispensable in the modern metal fabrication landscape. Their efficiency, precision, and versatility make them a preferred choice for manufacturers across various sectors. As we look to the future, the continuous advancements in technology will ensure that these machines remain at the forefront of metal processing, catering to the evolving needs of the industry while paving the way for sustainable practices. The importance of C channel rolling machines cannot be overstated; they are pivotal to both the functionality of modern infrastructure and the advancement of metal fabrication technology.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025