Optimizing Efficiency in C Channel Rolling Machinery for Enhanced Production

The C-Channel Rolling Machine A Key Element in Metal Fabrication

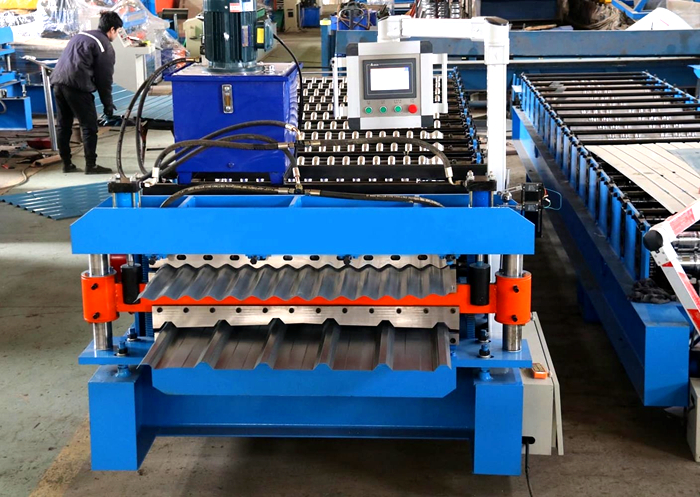

In the realm of metal fabrication, efficiency and precision are paramount. Among the various tools that aid in this process, the C-channel rolling machine stands out as a crucial piece of equipment for manufacturers and builders alike. This specialized machine is designed to fabricate C-shaped channels from metal sheets or strips, playing a vital role in constructing everything from structural frameworks to various consumer products.

The C-Channel Rolling Machine A Key Element in Metal Fabrication

One of the primary advantages of using a C-channel rolling machine is its ability to produce channels with a high level of consistency and quality. Traditional methods can often involve manual labor and varying degrees of accuracy, leading to discrepancies in the final product. In contrast, a rolling machine automates the process, significantly reducing the chances of human error. As a result, manufacturers can achieve tighter tolerances and more uniform material properties, which are critical in ensuring structural integrity.

c channel rolling machine

The versatility of C-channel rolling machines is another reason for their popularity in the industry. These machines are designed to handle various materials, including steel, aluminum, and other alloys. Additionally, they can accommodate different thicknesses and widths, catering to a wide range of project requirements. This adaptability makes them indispensable for manufacturers who need to respond to diverse demands across different sectors.

Moreover, innovations in C-channel rolling machines have led to the incorporation of CNC (Computer Numerical Control) technology. This advancement enables precise programming for varying channel specifications, allowing for quicker setup times and reduced production cycles. With the ability to automate complex tasks, manufacturers can increase their output while minimizing labor costs.

Furthermore, as the construction industry moves toward sustainable practices, the energy efficiency of modern C-channel rolling machines is worth noting. Many machines now consume less power, reducing the overall carbon footprint of metal fabrication processes. This shift not only aligns with environmental goals but also improves operational costs for manufacturers.

In conclusion, the C-channel rolling machine is an essential asset in the metal fabrication industry. Its ability to produce uniform, high-quality channels swiftly and efficiently makes it a valuable tool for construction and manufacturing. With ongoing advancements in technology, these machines continue to evolve, further enhancing their capabilities and solidifying their place in modern industrial processes. As demand for precision-engineered metal components rises, so too will the importance of C-channel rolling machines in meeting those needs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025