Cassette Production Line Using Advanced Roll Forming Technology for Efficient Manufacturing

The Advancements of Cassette Roll Forming Machines

In the modern era of manufacturing, precision, efficiency, and versatility have become paramount. Among various technologies developed to meet these demands, cassette roll forming machines stand out as a remarkable innovation. These specialized machines are designed to produce metal profiles efficiently and effectively, primarily for the construction and manufacturing industries. This article will delve into the features, benefits, and future of cassette roll forming machines.

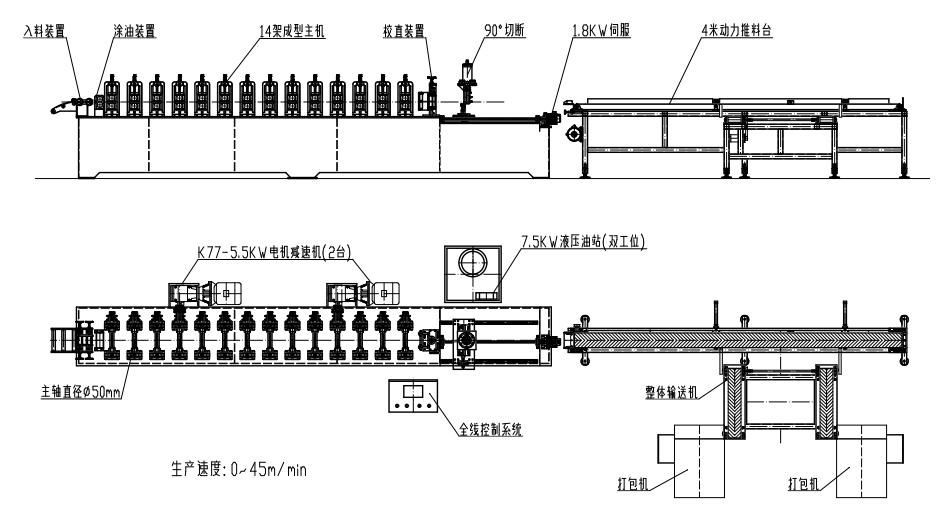

At its core, a cassette roll forming machine works by taking flat metal strips and passing them through a series of rollers. Each roller is meticulously designed to progressively shape the metal into a desired profile. The term cassette refers to the modular design of the machine, allowing quick and easy changes between different roll form profiles. This feature is particularly beneficial for manufacturers who need to produce various products in a short amount of time, fostering flexibility and adaptability in production lines.

One of the most significant advantages of cassette roll forming machines is their ability to enhance productivity. These machines are capable of running at high speeds while maintaining consistency in product quality. The automated nature of the process reduces human error and minimizes waste, allowing manufacturers to produce components more efficiently. As a result, businesses can meet increasing demands without sacrificing quality, leading to greater customer satisfaction and improved market competitiveness.

Moreover, cassette roll forming machines are not only efficient but are also cost-effective. The streamlined production process lowers labor costs, reduces material waste, and enhances energy efficiency. Over time, this results in significant savings for manufacturers, making the initial investment in such machinery worthwhile. Furthermore, the ability to produce a wide variety of profiles from a single machine adds to the overall cost-effectiveness, as companies can eliminate the need for multiple machines dedicated to specific profiles.

cassette roll forming machine

In terms of versatility, cassette roll forming machines can produce a broad range of profiles, from simple shapes to complex designs. This capability makes them ideal for various applications, including roofing, flooring, framing, and other structural components. The ability to switch between profiles quickly means that manufacturers can adapt to changing market demands, producing customized solutions for their clients without extended lead times.

Another noteworthy aspect of cassette roll forming machines is their adaptability to incorporate various materials. While they are predominantly used for steel, these machines can also handle aluminum, stainless steel, and other alloys. This adaptability opens up new markets and opportunities for manufacturers, allowing them to cater to different sectors and expand their product offerings.

Looking ahead, the future of cassette roll forming machines appears promising. With advancements in technology, including the integration of artificial intelligence (AI) and the Internet of Things (IoT), these machines are becoming smarter and more efficient. AI-powered systems can analyze production patterns, predict maintenance needs, and optimize operations in real time. This not only minimizes downtime but also enhances the overall efficiency of manufacturing processes.

Furthermore, as industries increasingly adopt sustainable practices, cassette roll forming machines will play a vital role in producing eco-friendly products. The ability to work with recycled materials and reduce waste aligns perfectly with the global shift towards sustainability. As the demand for green construction and manufacturing solutions rises, these machines will be pivotal in meeting that challenge.

In summary, cassette roll forming machines represent a significant leap forward in manufacturing technology. Their efficiency, cost-effectiveness, and versatility make them an invaluable asset for companies in various sectors. As technology continues to evolve, these machines are set to become even more sophisticated, positioning themselves as essential tools in the landscape of modern manufacturing. The future holds great potential for industries embracing the capabilities of cassette roll forming machines, paving the way for innovations that will define the next era of production.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025